Industrial Pallet Rack Inspection Checklist

Industrial Pallet Racks are designed to be heavy-duty and reliable, supporting their rated capacities effectively—provided they aren’t overloaded, misloaded, or damaged by forklift impacts. Forklift collisions can be particularly damaging to rack uprights. Although these systems can handle substantial weight and utilize vertical inventory space efficiently, undetected damage to an upright could compromise the entire system.

A rack collapse can potentially result in serious injuries, or worse, fatalities. Even if injuries are avoided, a rack collapse can cause significant inventory losses. Consequently, routine rack inspections are essential! If you discover any damage, we can't over-emphasize this enough, address it immediately.

Key Areas to Inspect

-

Rack Alignment:

- Ensure racks are aligned and level. Poor installation, or reconfigurations can lead to misalignment. Collisions can exacerbate issues in improperly set racks. Look for crooked racks or rows that are out of alignment.

-

Metal Condition:

- Check for rust or corrosion, which can weaken the metal. Scrapes on paint may indicate collision damage.

-

Load Capacity:

- Verify that racks aren’t overloaded. Overloading is a primary cause of rack failure. Always check load capacities, considering both beam and upright ratings, and ensure loads are within limits.

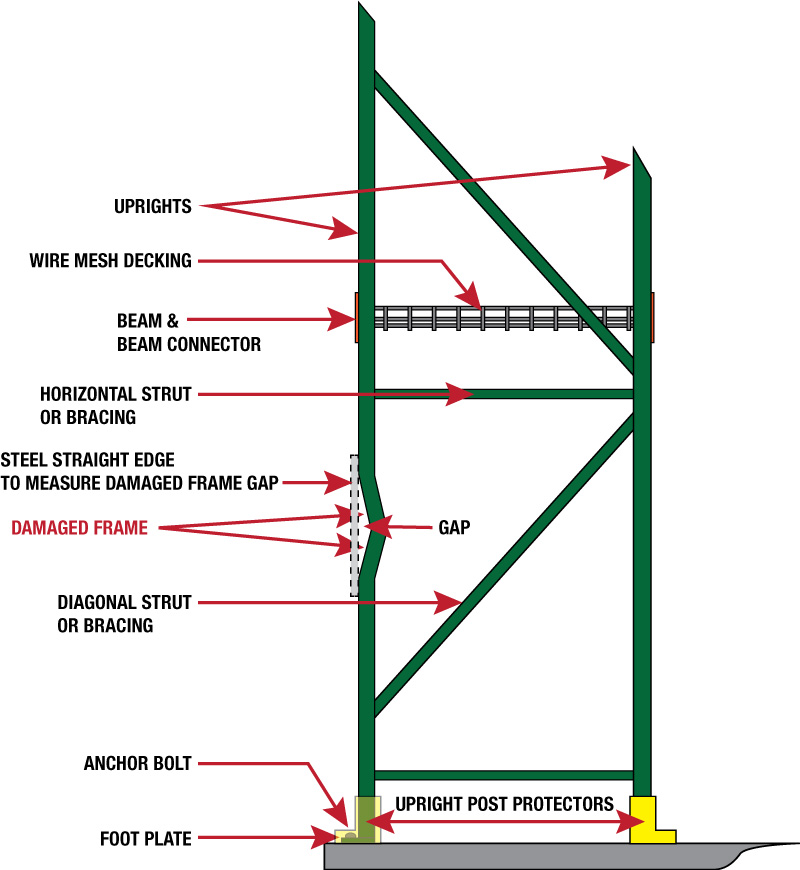

Upright Inspections

- Damage Assessment: Look for bent or damaged uprights, particularly if paint scrapes suggest forklift impacts. Even minor damage can reduce structural capacity. Replace or repair compromised uprights immediately.

- Horizontal Braces: Inspect for bending, twisting, or other damage.

- Footplates: Ensure they are securely attached and protected properly.

- Column Protectors: Check for damage and ensure that the upright has not been affected if protectors are damaged.

Damage Evaluation:

Measure gaps in damaged uprights using a steel straightedge. For uprights bent parallel to the beams, the maximum acceptable gap is 0.20" (5 mm). This standard applies to overall bends, not to dents or minor deformations.

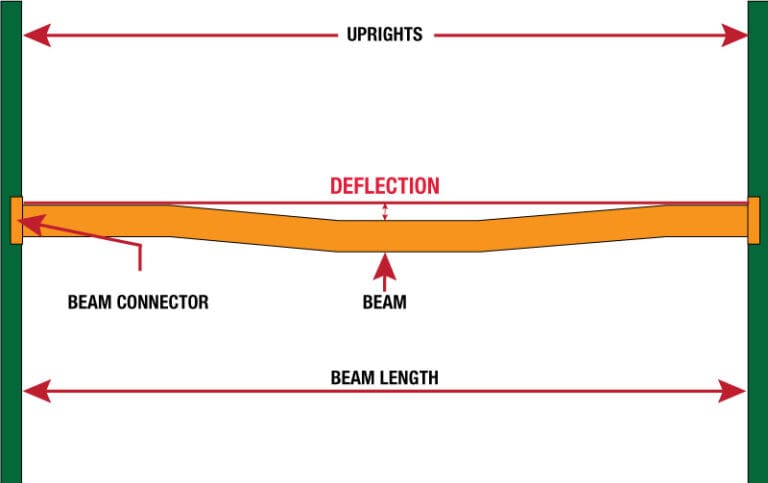

Load Beam Inspections

- Damage Check: Inspect for dents, twists, or scrapes. Replace damaged beams to prevent collapse.

- Deflection: Beams naturally bend under load, but excessive deflection (more than 1/180th of the beam length) indicates overloading or damage. Replace beams if deflection doesn’t return to normal after unloading.

- Beam Connections: Ensure beams are securely attached to uprights. Look for broken welds or damaged attachment points. Check that safety clips and bolts are tight.

- Connector Hardware: Inspect clips, bolts, safety pins, and attachment pins for damage or missing parts. Replace or tighten as needed and investigate the cause of any broken hardware.

While these guidelines offer a starting point, consulting a professional rack inspector will ensure your facility’s safety and rack integrity.