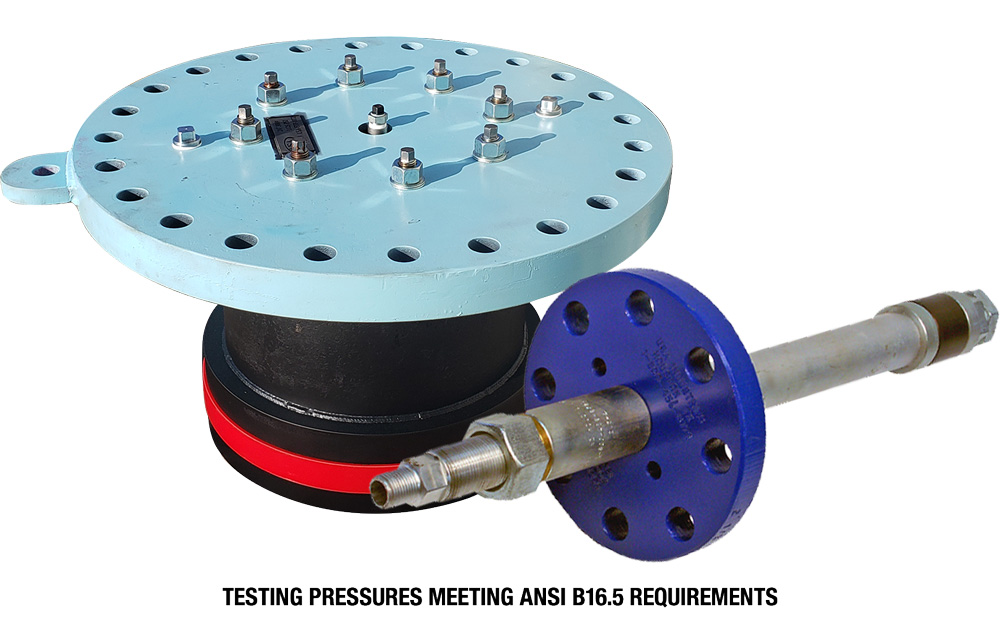

Flange Weld

Test Plug (FTP)

Money.

Rent.

Flange Weld Test Plugs (FTP) Specs:

- Stocked Line Sizes: 3/4" to 24"

- Flange Pressure Ratings: 150#, 300#, 600#, 900#, 1500#, 2500#

- Flange Types: Compatible with Raised-Face (RF) and Ring-Type Joint (RTJ) flanges

- Construction: Rugged, heavy-duty design for demanding applications

- Quality Assurance: Manufactured under USA Industries’ ISO 9001:2015 certified program

- Operational Efficiency: Enables faster pipe repairs and retrofits

- Installation & Testing: Safe, simple, and repeatable installation and test procedures

- Water Usage: Minimal water consumption; reduces handling and waste

- Cost Reduction: Lowers testing time, downtime, and waste disposal expenses

- Compatibility: Easily fits a wide range of pipe schedules

To Order Call: (800) 456-8721 — Specify:

- Flange Rating (150#, 300#, 600#, 900#, 1500#, 2500#)

- Size (3/4" - 24"*)

- Pipe Schedule

- Gasket Type

- Quantity Needed

- Rental or Purchase

- Necessary Delivery Date

*Larger sizes available upon request

ISOLATION/TEST PLUGS VS. WELDING END-CAPS

Isolation/Test plugs deliver faster turnarounds, lower costs, improved safety, and greater flexibility than welding end caps on pipe spools—transforming pressure testing from a bottleneck into a streamlined operation.

THE COMPARISON

GSST Isolation / Test Plugs

RecommendedWelding End-Caps

Legacy MethodWHY PLUGS WIN

Faster Turnarounds

Eliminate welding and grinding time. Go from installation to pressure testing in minutes, not hours—keeping your project schedule on track.

Lower Total Cost

Reusable plugs replace single-use caps, welder labor, consumables, and post-weld inspections. The ROI is immediate and compounding.

Improved Safety

Zero hot work means no fire watches, no arc flash risk, no fume exposure, and no hot work permits. A fundamentally safer process.

Greater Flexibility

Quickly adapt to changing test configurations. Reposition plugs across different spools and pipe sizes without rework or waste.

THE BOTTOM LINE

Isolation/Test plugs transform pressure testing from a bottleneck into a streamlined operation—delivering speed, savings, safety, and flexibility that welding end-caps simply cannot match.

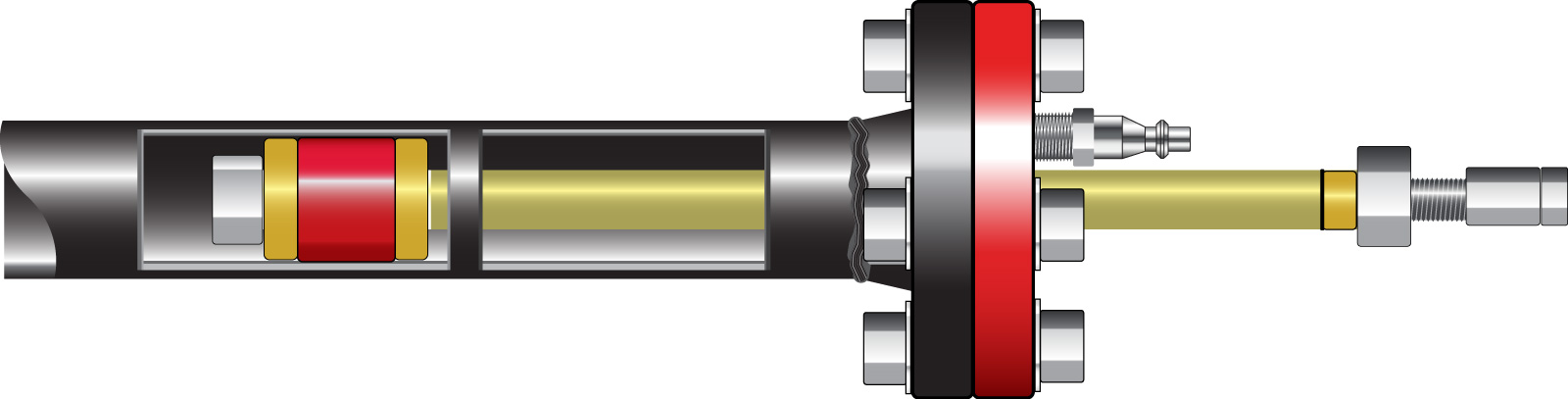

The Flange Weld Test Plug (FTP) by USA Industries simplifies the welding process by allowing you to monitor conditions, isolate and purge the weld area, and complete the weld and hydrotest to meet code requirements—all with one tool. The FTP features a high-lift seal that expands, providing a greater seal-to-pipe clearance. This eliminates the need to grind excess root penetration, making it convenient to move past the weld.

INSTALLATION IS FAST AND EASY!

To install the Flange Weld Test Plug simply insert the plug into the pipe to be welded, bolt the flanges together, and tighten the large compression nut(s) to expand the seal. The weld area is fully isolated, eliminating the need to fill the entire line or vessel. This not only simplifies the process but also reduces hazardous waste disposal costs. The FTP requires only a minimal amount of water for testing, ranging from a few cups to a few gallons depending on the line size. By reducing costs, downtime delays, and environmental impact, the FTP eliminates the need for line blinds, vacuum trucks, or dehydration services. It also minimizes non-destructive examination (NDE) requirements.

A Critical Reminder: Conducting pressure testing poses significant hazards, demanding strict adherence to safety protocols. Ensure all connections, valves, flanges, and fittings are suitable for pressure testing. Verify the compatibility of line ID & Plug Range. Most importantly, never position yourself in front of a test plug or enclosure during testing. Discharge from a plug during testing could result in severe injury or fatality.

FTP Technical Documentation

Frequently Asked Questions

Yes, if you have a restriction on the inside or outside of the pipe that you're testing we can make it shorter or longer. Just let us know what you need!

Yes, if you've already purchased a Flange Weld Test Plug from us and need replacement seals, we've got you covered. We have them in stock and ready to go for all common sizes.

Yes, these plugs are rated for the hydro pressure of the blind flange.

The seal is made of urethane.

Yes, we can put venting into your Flange Weld Test Plug upon request.

Yes, this is completely customizable. Give us a call today and we'll help you customize your plug.

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Engineering Innovation

Precision-Engineered Industrial Solutions — Delivered Fast!

100% USA Materials

All raw materials sourced from American mills.