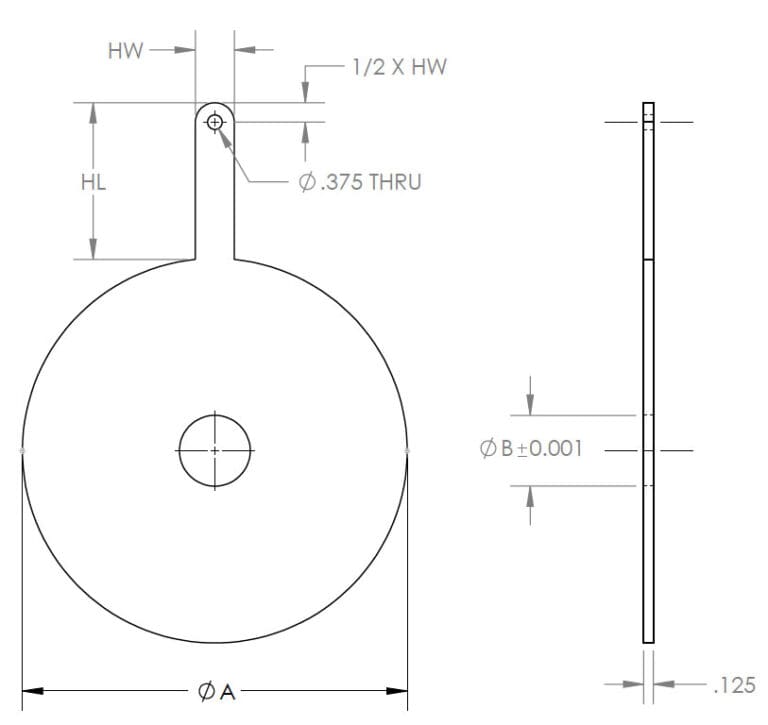

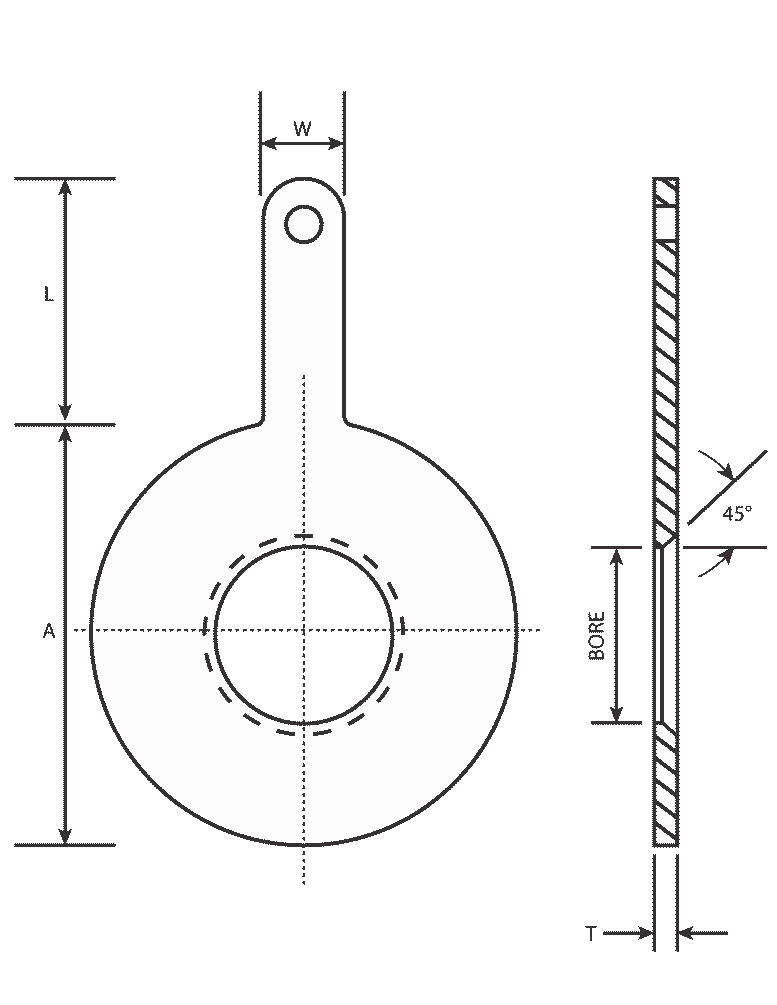

Paddle Type Orifice Plates (Series 520)

Series 520 Paddle Type Plates are manufactured for use with Raised Face Orifice Flanges, Flat Face Flanges, and Holding Blocks

SERIES 520 - PADDLE TYPE ORIFICE PLATE FEATURES & BENEFITS:

- Meets or exceeds AGA, ISA, ANSI, ASME & API standards

- Precision CNC machining for superior accuracy and quality control

- Simple to use and easy to troubleshoot

- Minimal maintenance required

- Stocked materials: 304/316 Stainless Steels; available in any material requested

- Fast and accurate orifice bore calculation services available

- USA Industries will provide coatings upon request

- In-stock items ship within 24 hours, same day local delivery ability in Texas

Employing cutting-edge CNC machines, we produce our Paddle-Type Orifice Plates that adhere to the strictest manufacturing processes and achieve optimal accuracy standards. Our team of trained mechanical engineers can swiftly and accurately run your bore calculations for an additional fee.

Series 520 Paddle Type Orifice Plates are designed for use with Raised Face Orifice Flanges and Holding Blocks, that meet or exceeding AGA, ISA, ANSI, ASME, API & AWWA standards. Crafted by skilled CNC operators, these plates ensure top quality.

We stock our plates in 304 & 316 stainless steels, and can manufacture them in any material you prefer, including monel, hastelloy, copper, nickel, and more. USA Industries also offers the option to coat your orifice plates with any specified coating.

NEED A BORE CALCULATION?

Let USA Industries' engineers calculate the correct bore size based on process data for the project.

Select Flange Rating to See Specifications

| 150# Flange Rating | ||||

|---|---|---|---|---|

| Line Size | A | HL | HW | T |

| 1/2" | 1 7/8" | 4" | 1" | 1/8" |

| 3/4" | 2 1/4" | |||

| 1" | 2 5/8" | |||

| 1 1/4" | 3" | |||

| 1 1/2" | 3 3/8" | |||

| 2" | 4 1/8" | |||

| 2 1/2" | 4 7/8" | |||

| 3" | 5 3/8" | |||

| 4" | 6 7/8" | |||

| 5" | 7 3/4" | |||

| 6" | 8 3/4" | |||

| 8" | 11" | 1/4" | ||

| 10" | 13 3/8" | 6" | 1 1/2" | |

| 12" | 16 1/8" | |||

| 14" | 17 3/4" | |||

| 16" | 20 1/4" | 3/8" | ||

| 18" | 21 1/2" | |||

| 20" | 23 3/4" | |||

| 22" | 26" | |||

| 24" | 28 1/8" | 1/2" | ||

| 30" | 34 5/8" | |||

| 36" | 41 1/8" | |||

| 300# Flange Rating | ||||

|---|---|---|---|---|

| Line Size | A | HL | HW | T |

| 1/2" | 2 1/8" | 4" | 1" | 1/8" |

| 3/4" | 2 5/8" | |||

| 1" | 2 7/8" | |||

| 1 1/4" | 3 1/4" | |||

| 1 1/2" | 3 3/4" | |||

| 2" | 4 3/8" | |||

| 2 1/2" | 5 1/8" | |||

| 3" | 5 7/8" | |||

| 4" | 7 1/8" | |||

| 5" | 8 1/2" | |||

| 6" | 9 7/8" | |||

| 8" | 12 1/8" | 1/4" | ||

| 10" | 14 1/4" | 6" | 1 1/2" | |

| 12" | 16 5/8" | |||

| 14" | 19 1/8" | |||

| 16" | 21 1/4" | 3/8" | ||

| 18" | 23 3/8" | |||

| 20" | 25 5/8" | |||

| 22" | 27 3/4" | |||

| 24" | 30 3/8" | 1/2" | ||

| 30" | 37 3/8" | |||

| 36" | 43 7/8" | |||

| 400# Flange Rating | ||||

|---|---|---|---|---|

| Line Size | A | HL | HW | T |

| 1/2" | 2 1/8" | 4" | 1" | 1/8" |

| 3/4" | 2 5/8" | |||

| 1" | 2 7/8" | |||

| 1 1/4" | 3 1/4" | |||

| 1 1/2" | 3 3/4" | |||

| 2" | 4 3/8" | |||

| 2 1/2" | 5 1/8" | |||

| 3" | 5 7/8" | |||

| 4" | 7" | |||

| 5" | 8 3/8" | |||

| 6" | 9 3/4" | |||

| 8" | 12" | 1/4" | ||

| 10" | 14 1/8" | 6" | 1 1/2" | |

| 12" | 16 1/2" | |||

| 14" | 19" | |||

| 16" | 21 1/8" | 3/8" | ||

| 18" | 23 1/4" | |||

| 20" | 25 3/8" | |||

| 22" | 27 1/2" | |||

| 24" | 30 1/8" | 1/2" | ||

| 30" | 37 1/4" | |||

| 36" | 43 7/8" | |||

| 600# Flange Rating | ||||

|---|---|---|---|---|

| Line Size | A | HL | HW | T |

| 1/2" | 2 1/8" | 4" | 1" | 1/8" |

| 3/4" | 2 5/8" | |||

| 1" | 2 7/8" | |||

| 1 1/4" | 3 1/4" | |||

| 1 1/2" | 3 3/4" | |||

| 2" | 4 3/8" | |||

| 2 1/2" | 5 1/8" | |||

| 3" | 5 7/8" | |||

| 4" | 7 5/8" | |||

| 5" | 9 1/2" | |||

| 6" | 10 1/2" | |||

| 8" | 12 5/8" | 1/4" | ||

| 10" | 15 3/4" | 6" | 1 1/2" | |

| 12" | 18" | |||

| 14" | 19 3/8" | |||

| 16" | 22 1/4" | 3/8" | ||

| 18" | 24" | |||

| 20" | 26 3/4" | |||

| 22" | 28 7/8" | |||

| 24" | 31" | 1/2" | ||

| 30" | 38 1/8" | |||

| 36" | 44 3/8" | |||

| 900# Flange Rating | ||||

|---|---|---|---|---|

| Line Size | A | HL | HW | T |

| 1/2" | 2 1/2" | 4" | 1" | 1/8" |

| 3/4" | 2 3/4" | |||

| 1" | 3 1/8" | |||

| 1 1/4" | 3 1/2" | |||

| 1 1/2" | 3 7/8" | |||

| 2" | 5 5/8" | |||

| 2 1/2" | 6 1/2" | |||

| 3" | 6 5/8" | |||

| 4" | 8 1/8" | |||

| 5" | 9 3/4" | |||

| 6" | 11 3/8" | |||

| 8" | 14 1/8" | 1/4" | ||

| 10" | 17 1/8" | 6" | 1 1/2" | |

| 12" | 19 5/8" | |||

| 14" | 20 1/2" | |||

| 16" | 22 5/8" | 3/8" | ||

| 18" | 25" | |||

| 20" | 27 3/8" | |||

| 22" | - | |||

| 24" | 32 7/8" | 1/2" | ||

| 30" | - | |||

| 36" | - | |||

| 1500# Flange Rating | ||||

|---|---|---|---|---|

| Line Size | A | HL | HW | T |

| 1/2" | 2 1/2" | 4" | 1" | 1/8" |

| 3/4" | 2 3/4" | |||

| 1" | 3 1/8" | |||

| 1 1/4" | 3 1/2" | |||

| 1 1/2" | 3 7/8" | |||

| 2" | 5 5/8" | |||

| 2 1/2" | 6 1/2" | |||

| 3" | 6 7/8" | |||

| 4" | 8 1/4" | |||

| 5" | 10" | |||

| 6" | 11 1/8" | |||

| 8" | 13 7/8" | 1/4" | ||

| 10" | 17 1/8" | 6" | 1 1/2" | |

| 12" | 20 1/2" | |||

| 14" | 22 3/4" | |||

| 16" | 25 1/4" | 3/8" | ||

| 18" | 27 5/8" | |||

| 20" | 29 5/8" | |||

| 22" | - | |||

| 24" | 35 1/2" | 1/2" | ||

| 30" | - | |||

| 36" | - | |||

| 2500# Flange Rating | ||||

|---|---|---|---|---|

| Line Size | A | HL | HW | T |

| 1/2" | 2 3/4" | 4" | 1" | 1/8" |

| 3/4" | 3" | |||

| 1" | 3 3/8" | |||

| 1 1/4" | 4 1/8" | |||

| 1 1/2" | 4 5/8" | |||

| 2" | 5 3/4" | |||

| 2 1/2" | 6 5/8" | |||

| 3" | 7 3/4" | |||

| 4" | 9 1/4" | |||

| 5" | 11" | |||

| 6" | 12 1/8" | |||

| 8" | 15 1/4" | 1/4" | ||

| 10" | 18 3/4" | 6" | 1 1/2" | |

| 12" | 21 5/8" | |||

| 14" | - | |||

| 16" | - | 3/8" | ||

| 18" | - | |||

| 20" | - | |||

| 22" | - | |||

| 24" | - | 1/2" | ||

| 30" | - | |||

| 36" | - | |||

| Flange Rating | ||||

|---|---|---|---|---|

| Line Size | A | HL | HW | T |

Note: USA Industries orifice bore calculation service is provided on a professional fee basis.

Frequently Asked Questions

Yes, we typically use the bore calculations provided to us by the customer, but we can do the bore calculations upon request for a small additional fee.

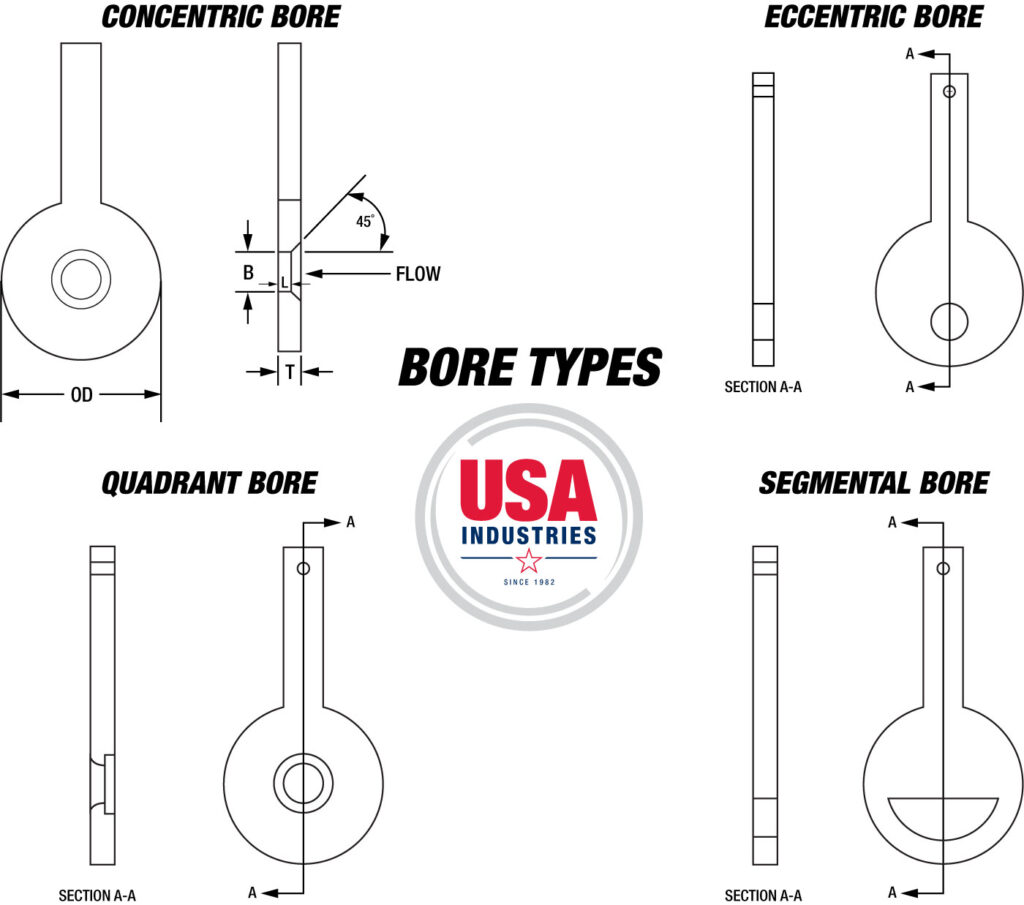

Yes, our four bore options are concentric, eccentric, quadrant and segment.

Yes, we're happy to engineer in a vent or drain. Let us know your specs and we'll manufacture it to meet your exact needs.

Yes, we can completely customize your orifice plates to your unique needs.

We stock our orifice plates in 304 & 316 stainless steel, but they are available in any material requested. We have produced orifice plates for clients in everything from monel to hastelloy to copper-nickel alloys and more!