Bleed Rings

The easiest, safest and quickest way to drain piping or a bleed valve.

Bleed Rings, also known as drip rings or bleed rings, are used in piping systems to provide a means for relieving pressure, draining fluids, or sampling process media from pipelines or vessels. These rings are typically installed between two flanges and feature one or more radial or tangential ports that allow for the controlled release of fluids or gases.

BLEED RINGS PRODUCT FEATURE:

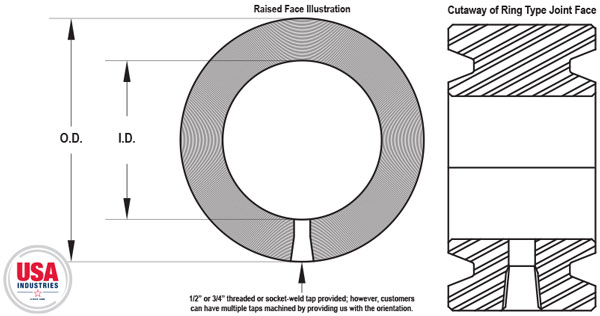

- We manufacture to ASME/ANSI B16.5 and B16.20 specs for raised face and ring type joint (RTJ) dimensions and tolerances

- Stand materials include Carbon Steel (516-Gr70 & A105/LF-2) and Stainless Steel (304 & 316)

- Choose between 1/2" or 3/4" threaded or socket-weld connections as well as raised-face (125-250 RMS) or ring type joint (RTJ) configurations (male or female)

- Standard Ring Joints (RJ) feature female oval ring grooves (male joints are available upon request)

- Carbon steel plate products receive one coat of black lacquer as standard, unless alternative specifications are provided

- Customizable! Material, size, tap connections and sizes, gasket types, # of ports

- In-stock items ship within 24 hours

Bleed Ring 3D Product Rotation

BLEED RING PRIMARY USES:

A primary function is to provide a safe and controlled way to relieve excess pressure from a pipeline or vessel. In situations where pressure buildup occurs due to thermal expansion, equipment malfunctions, or process upsets, bleed rings allow operators to release a small amount of fluid or gas to alleviate pressure and prevent damage to the system. By maintaining pressure within safe operating limits, bleed rings help safeguard equipment, personnel, and the environment from the risks associated with overpressurization.

Further, bleed rings serve as access points for draining fluids or sampling process media from pipelines or vessels. These rings enable operators to collect samples for analysis, perform quality control checks, or conduct maintenance activities without the need to depressurize or dismantle the entire system. By providing convenient access to process fluids, bleed rings facilitate efficient and cost-effective operations while minimizing downtime and disruption to production processes.

Bleed Ring Dimensions

| Line Size | O.D. | I.D. | ||||

|---|---|---|---|---|---|---|

| 150# | 300# | 600# | 900# | 1500# | ||

| .50 | 1.75 | 2.00 | 2.00 | 2.375 | 2.375 | .625 |

| .75 | 2.125 | 2.50 | 2.50 | 2.625 | 2.625 | .875 |

| 1.00 | 2.50 | 2.75 | 2.75 | 3.00 | 3.00 | 1.32 |

| 1.50 | 3.25 | 3.625 | 3.625 | 3.75 | 3.75 | 1.90 |

| 2.00 | 4.00 | 4.25 | 4.25 | 5.50 | 5.50 | 2.375 |

| 2.50 | 4.75 | 5.00 | 5.00 | 6.375 | 6.375 | 2.875 |

| 3.00 | 5.25 | 5.75 | 5.75 | 6.5 | 6.75 | 3.50 |

| 4.00 | 6.75 | 7.00 | 7.50 | 8.00 | 8.125 | 4.50 |

| 6.00 | 8.625 | 9.75 | 10.375 | 11.25 | 11.00 | 6.625 |

| 8.00 | 10.875 | 12.00 | 12.50 | 14.00 | 13.75 | 8.625 |

| 10.00 | 13.25 | 14.125 | 15.625 | 17.00 | 17.00 | 10.75 |

| 12.00 | 16.00 | 16.50 | 17.75 | 19.325 | 20.25 | 12.75 |

| 14.00 | 17.625 | 19.00 | 19.125 | 20.25 | 22.50 | 14.00 |

| 16.00 | 20.125 | 21.125 | 22.00 | 22.375 | 25.00 | 16.00 |

| 18.00 | 21.50 | 23.375 | 23.875 | 24.875 | 27.50 | 18.00 |

| 20.00 | 23.75 | 25.625 | 26.625 | 27.25 | 29.50 | 20.00 |

| 24.00 | 28.125 | 30.375 | 30.875 | 32.75 | 35.25 | 24.00 |

Frequently Asked Questions

Yes, multiple NPT ports can be added upon request.

Yes, we can add a larger tap, but the thickness may need to be adjusted to accommodate this.

They are typically 1.5" thick, but can be made in other thicknesses upon request. Your studs will need to accommodate the space of the bleed ring and flanges.

Yes. We regularly provide Bleed Ring / Drip Ring / Vent Ring with socket weld taps.

Yes, we can custom manufacture our bleed rings the way you require.

We primarily manufacture our bleed rings in 304 and 316 stainless steel, but we can make them in any material you need.

Yes, as the manufacturer we can customize any of our products to your exact specifications.

Absolutely! A large bleed ring is not a problem. We can go up to 80" O.D. on our lathes, and can customize solutions for even larger diameters when needed. Let us know what you need, and we'll be happy to manufacture it for you.