Critical Piping Isolation for a Landmark LNG Project

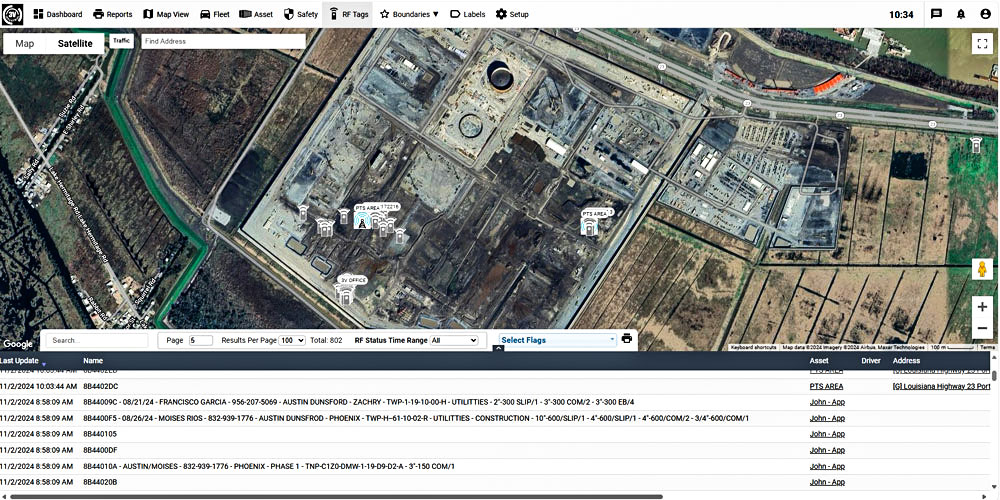

Plaquemine LNG Plant Critical Piping Isolation for a Landmark LNG Project

PROJECT BACKGROUND

The Plaquemine LNG facility in Plaquemine, Louisiana is one of the most ambitious energy infrastructure projects in the U.S.—and reliability was non-negotiable.

USA Industries played a key role by supplying engineered piping isolation solutions designed to prevent leaks, reduce risk, and keep construction moving. Manufactured to ISO 9001:2015 standards, these products were built for fast installation, long-term durability, and uncompromising safety.

Beyond the products, USA Industries provided hands-on, on-site support—managing inventory and working closely with 3V Industrial to ensure materials were available exactly when needed. This collaborative approach helped streamline installation, meet critical milestones, and ultimately beat the plant’s scheduled opening date.

As the facility transitions into operation, USA Industries’ piping isolation solutions continue to protect system integrity and support long-term reliability—helping power a cleaner energy future.

THE CHALLENGE:

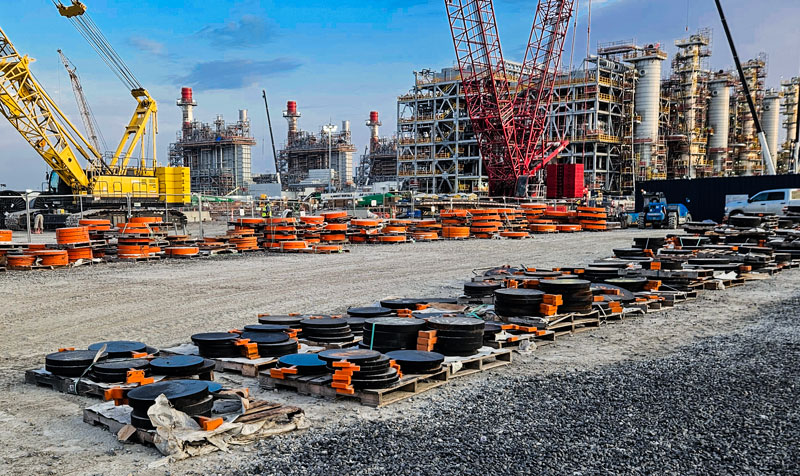

The scale and complexity of the Plaquemine LNG project presented significant challenges:

- Extensive and intricate piping systems/li>

- Zero tolerance for leaks, safety incidents, or environmental risk

- Tight construction schedules with high consequences for downtime

- Any failure in piping isolation could have resulted in costly delays, safety hazards, or long-term operational risk.

USA INDUSTRIES' SOLUTION

USA Industries supplied advanced piping isolation products specifically engineered to mitigate risk and support large-scale LNG construction. Manufactured in strict compliance with ISO 9001:2015 quality standards, these solutions were designed for:

- Leak prevention and system integrity

- Ease of installation, reducing labor hours and complexity

- Durability and reliability to meet long-term operational demands

Beyond the products themselves, USA Industries provided hands-on customer support, including dedicated resources to manage product inventory directly on-site—ensuring materials were available exactly when needed.

EXECUTION AND ON-SITE PARTNERSHIP

Execution & On-Site Partnership

A key differentiator in the project’s success was the close partnership between USA Industries and 3V Industrial. This collaboration enabled:

- Efficient on-site inventory management

- Streamlined communication between teams

- Rapid response to changing project needs

- Dedicated personnel supporting daily operations

The strength of this partnership allowed the project team to maintain momentum, meet critical milestones, and ultimately beat the plant’s scheduled opening date.

RESULTS

- Enhanced safety and reduced risk across critical piping systems

- Faster installation and reduced labor time during construction

- Reliable protection of piping infrastructure from day one

- On-time—and early—project completion through coordinated execution

USA Industries’ solutions met both immediate construction needs and long-term operational requirements, ensuring the plant’s piping systems were protected from startup through full operation.

LONG-TERM IMPACT

As the Plaquemine LNG facility transitions into full operation, USA Industries’ piping isolation solutions continue to deliver value. Their reliability and durability support ongoing maintenance, system integrity, and operational efficiency—helping extend the plant’s lifecycle and minimize future risk.

By delivering proven solutions and on-site expertise, USA Industries is proud to support critical energy infrastructure projects that help meet global demand for cleaner, more reliable energy.