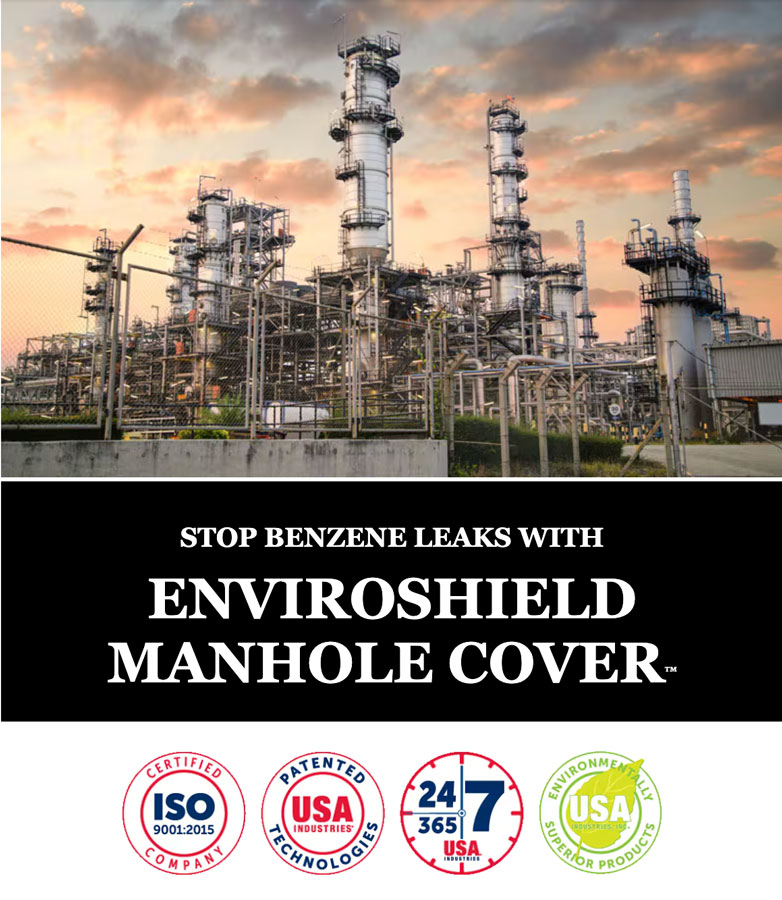

The EPA has implemented strict regulations to control toxic air emissions from petroleum refineries, chemical plants, terminals, storage facilities, wastewater facilities among others, including harmful compounds like benzene. To help meet these benzene emission standards, USA Industries, in partnership with RFS Compliance Solutions engineered the EnviroShield™ Manhole Cover — a proven solution for benzene mitigation and emission control. EPA compliance requires plants to continuously monitor emissions at key sources and along facility fencelines. The EnviroShield Manhole Cover provides a reliable mechanical seal that prevents leaks and reduces fugitive benzene emissions from refinery piping systems.

- Benzene, a known human carcinogen, poses significant health risks, making its emission reduction a public health priority.

- The National Emission Standards for Hazardous Air Pollutants (NESHAP) aim to cut hazardous air pollutants, including benzene, by 53,000 tons annually.

- Under the updated monitoring rules, refineries must track benzene emissions and take corrective action if emissions exceed the EPA’s established threshold.

- By the end of 2023, only six out of 109 U.S. refineries surpassed this threshold, demonstrating the effectiveness of these regulations.

Factors contributing to benzene emissions in refineries:

- Storage tanks: Leaks from storage tanks containing crude oil or refined products can release benzene emmissions into the atmosphere.

- Process equipment leaks: Leaks from pipes, valves, and other equipment during the refining process are dire and require benzene mitigation.

- Wastewater treatment: Improper management of wastewater can lead to benzene emissions.

Efforts to reduce benzene emissions:

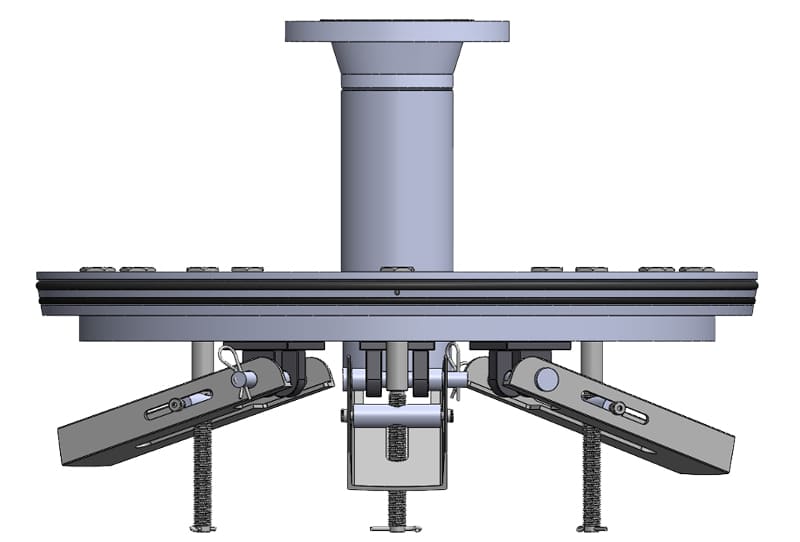

- Install mechanical benzene mitigation solutions to seal off leaking pipes.

- Replace seals and gaskets: Replacing worn components on pumps, valves, and flanges to minimize leaks.

- Improved maintenance practices: Regularly inspecting and repairing leaks on storage tanks and process equipment.

- Vapor recovery systems: Installing systems to capture and recover vapors released during loading and unloading operations.

- Process modifications: Implementing changes to refining processes to minimize benzene production.

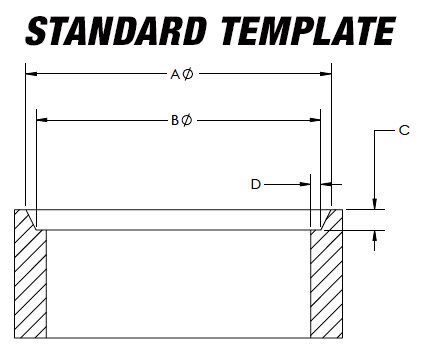

Measurement Requirements

Measurement Requirements