Product Description

Tube end facers for heat exchangers prepare the ends of tubes used in heat exchangers, condensers, and boilers. These specialized tools ensure each tube end is smooth, clean, and properly aligned for welding, rolling, or other joining processes. By creating a precise, perpendicular face on the tube, tube end facers prevent leaks and boost the efficiency and lifespan of the heat exchanger.

The tools remove burrs, irregularities, or damaged material from the tube ends. This step becomes critical when the tube-to-tube sheet joint must form a complete seal under high-pressure or high-temperature conditions. Any flaw at the tube end can compromise the seal, leading to performance issues or system failure.

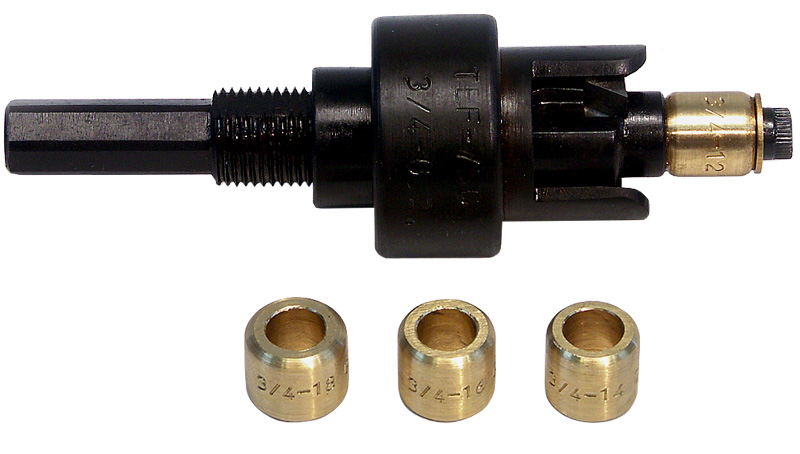

Operators can easily transport and operate these tools, even in confined or on-site workspaces. Manufacturers offer tube end facers in multiple sizes and configurations to fit various tube diameters and materials. For best results, pair this tool with our electric or pneumatic roll motors to maintain consistency across a range of tube sizes.

Professionals in industries such as power generation, oil and gas, chemical processing, and HVAC rely on these tools, where heat exchangers serve as vital components. USA Industries engineers its tube end facers for precision, durability, and ease of use—ensuring operators consistently achieve high-quality results with minimal training.