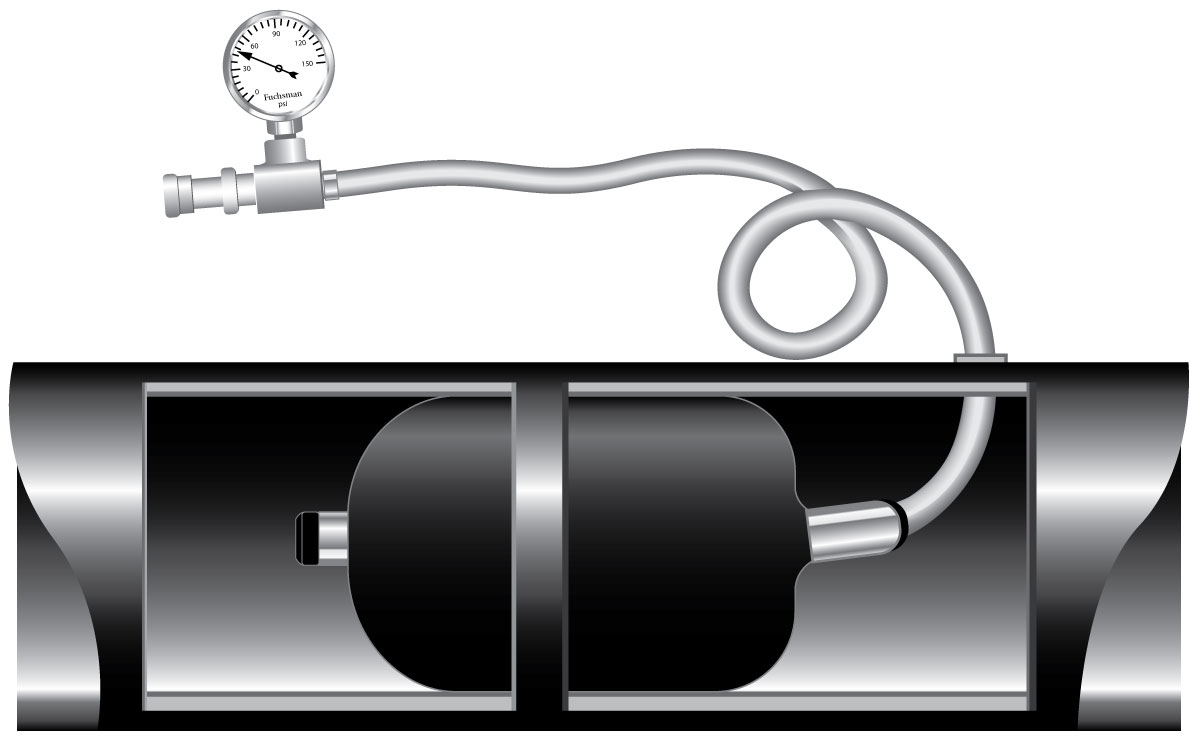

Medium Pressure

Inflatable Pipe Plug

Money.

Rent.

To Order Call: (800) 456-8721 — Specify:

- Size (1/2" - 96")

- Test Pressure

- Quantity Needed

- Rental or Purchase

- Necessary Delivery Date

Medium Pressure Inflatable Pipe Plug Specs:

- Available Sizes: 2" to 96"

- Construction: Ballistic-nylon–reinforced nitrile outer shell with a high-quality polyurethane inner bladder

- Chemical Resistance: Hydrocarbon-resistant materials for industrial environments

- Durability: Puncture- and tear-resistant construction for reliable field use

- Temperature Rating: Heat-resistant materials safe for operation up to 200°F

- Included Accessories: Supplied with pressure gauge and 2 ft. inflation hose; extended hose lengths available upon request

- Expansion Range: Flexible, expandable design conforms to a wide range of internal pipe diameters; supports partial and full inflation

- Usage Profile: Optimized for short-term or temporary isolation applications

- Origin: Manufactured in the USA

Additional Notes (optional enhancements):

- Low back-pressure design suitable for gravity-flow or low-pressure systems

- Lightweight construction for easier handling in the field

- Compatible with standard air-source fittings for quick inflation and deflation

NOTE: DO NOT EXCEED recommended back-pressure holding limit*

*If holding backpressure is a requirement, ask us about our new and exclusive GripSafe®ST isolation and test plugs, or one of our other low to high pressure rated high quality plugs

ISOLATION/TEST PLUGS VS. WELDING END-CAPS

Isolation/Test plugs deliver faster turnarounds, lower costs, improved safety, and greater flexibility than welding end caps on pipe spools—transforming pressure testing from a bottleneck into a streamlined operation.

THE COMPARISON

GSST Isolation / Test Plugs

RecommendedWelding End-Caps

Legacy MethodWHY PLUGS WIN

Faster Turnarounds

Eliminate welding and grinding time. Go from installation to pressure testing in minutes, not hours—keeping your project schedule on track.

Lower Total Cost

Reusable plugs replace single-use caps, welder labor, consumables, and post-weld inspections. The ROI is immediate and compounding.

Improved Safety

Zero hot work means no fire watches, no arc flash risk, no fume exposure, and no hot work permits. A fundamentally safer process.

Greater Flexibility

Quickly adapt to changing test configurations. Reposition plugs across different spools and pipe sizes without rework or waste.

THE BOTTOM LINE

Isolation/Test plugs transform pressure testing from a bottleneck into a streamlined operation—delivering speed, savings, safety, and flexibility that welding end-caps simply cannot match.

INFLATABLE PIPE PLUG KEY BENEFITS

- Temporary Pipe Blockage: Quickly blocks the flow of liquids or gases for maintenance, repairs, or testing without permanent modifications or shutdowns.

- Versatility: Fits pipe sizes 1.5" - 66", usable in various systems (sewer, stormwater, industrial, plumbing), and can be snaked into large, inaccessible pipes.

- Quick and Easy Installation: Fast setup with minimal effort, featuring a simple inflation valve for quick adjustment to the desired pressure.

- Effective Sealing: Creates a tight seal to prevent leaks, spills, or contamination during maintenance.

- Cost-Effectiveness: Lower cost than mechanical plugs or hot taps; reusable and requires minimal equipment and labor.

- Safety: Durable, safe materials that withstand harsh environments, easily deflated and removed to minimize risks.

Do not over-inflate inflatable pipe plugs beyond the pressure specified in the specifications to each stopper. The pressures are detailed in the accompanying table.

A Critical Reminder: Conducting pressure testing poses significant hazards, demanding strict adherence to safety protocols. Ensure all connections, valves, flanges, and fittings are suitable for pressure testing. Verify the compatibility of line ID & Plug Range. Most importantly, never position yourself in front of a test plug or enclosure during testing. Discharge from a plug during testing could result in severe injury or fatality.

Technical Documentation

Frequently Asked Questions

Typically not on our canvas plugs, but we can provide a different style that does have vent through capabilities.

We have provided inflatable pipe plugs up to 66". If you need a larger size we can provide other solutions for you!

Yes, let us know what size hose you need.

Our inflatable pipe plug is available in heat resistant materials that can be safe for use up to 200°F.

Although they can hold a few pounds, we do not recommend these be used for holding back pressure unless it's for water and there would be a negligible impact if they failed.

The only thing that can be repaired is the valve stem inner fill stem.

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Engineering Innovation

Precision-Engineered Industrial Solutions — Delivered Fast!

100% USA Materials

All raw materials sourced from American mills.