Rod Out Tools

Bleeder Cleaners

Drain

Vent

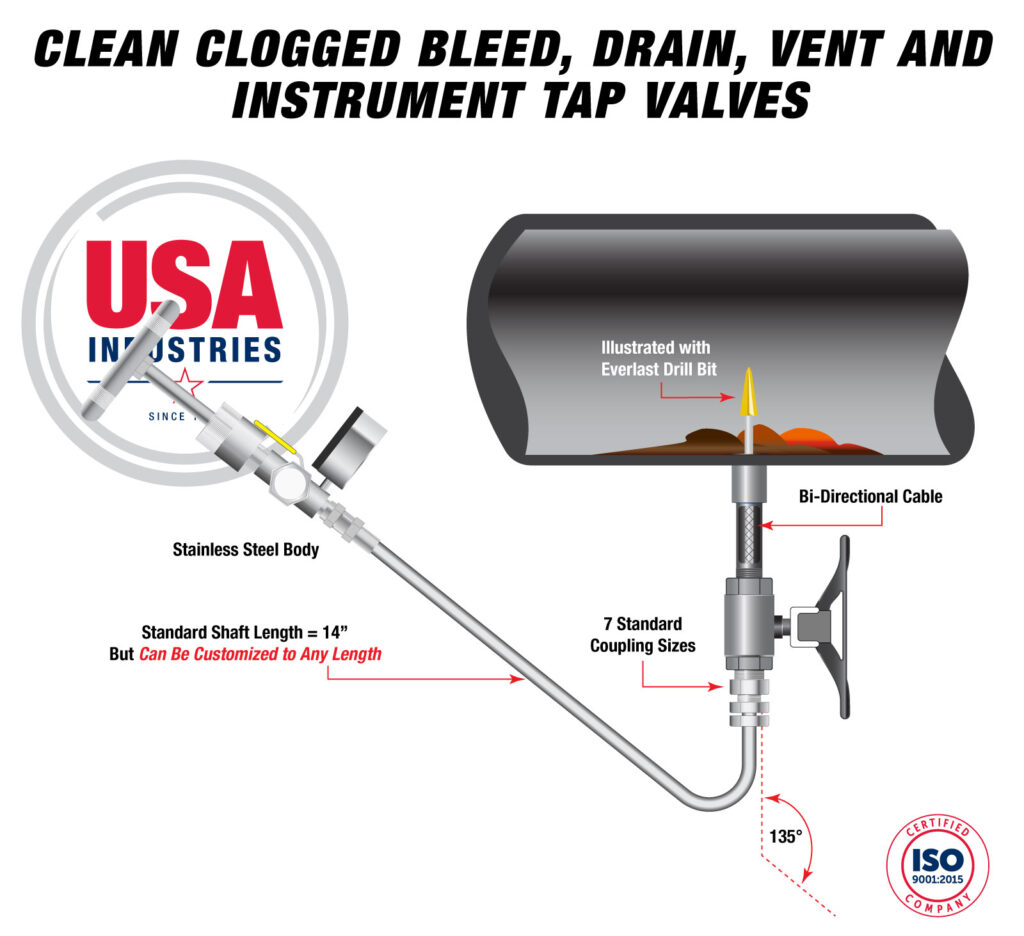

Rod Out Tool (Bleeder Cleaner) Specs:

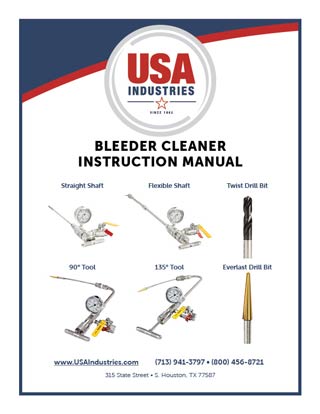

| Shaft Configuration Types: | 90˚, 135˚, Straight & Flexible |

| Bit Types: | Everlast & Twist |

| Common Twist Bit Sizes: | 1/4" | 5/16" | 3/8" | 7/16" | 1/2" | 3/4" (custom sizes available) |

| Common Coupling Sizes: | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 1-3/4" | 2" (custom sizes available) |

| Standard Shaft Length: | 14" (longer shafts available upon request) |

| Temperature & Pressure Ratings: | up to 1000˚F & 1000 PSIG respectively |

| Standards Conformation: | ANSI | ASME | ASTM for dimensions |

- Same-day local shipping/delivery available in Texas and Lousiana

- New generation bleeder cleaners allow field-replacement of parts, eliminating the need for factory maintenance

For custom requirements, USA Industries offers tailored solutions under our ISO 9001:2015 quality-assurance program.

To Order Call: (800) 456-8721 — Specify:

- Length of Shaft (standard is 14")

- Shaft Type (Straight, 90˚, 135˚, Flexible)

- Drill Bit Type & Size (Everlast, Twist Bit - most common: 1/4" | 5/16" | 3/8" | 7/16" | 1/2" | 3/4")

- Coupling Size (most common: 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 1-3/4" | 2")

- Quantity Needed

- Necessary Delivery Date

When used correctly, our Rod Out Tool eliminates dangerous exposure, vapor releases explosions, and fires when clearing bleeder valves, vents, drains, and instrument taps during normal operations.

BLEEDER CLEANER EASE OF USE:

- Screw the end connector onto the item needing cleaning.

- Close the bleed valve and open the process valve.

- Insert the shaft while rotating the handle.

- After clearing the line, back out the shaft, close the process valve, open the bleed valve, and disconnect the tool.

Technical Documentation

Frequently Asked Questions

Yes, bi-directional cables can be provided upon request.

Yes, you can always send us your tools for inspection. We can then evaluate it and repair it as necessary.

Easy, just turn the rodout handle to the right continuously to safely and efficiently clean clogged bleed, drain, vent & instrument tap valves.

No, the bits are soldered in place permanently.

The Twist drill bit and Everlast drill bit are available from USA Industries.

No, the handle should only be turned by hand. Using an impact may damage your bleeder cleaner or tap.