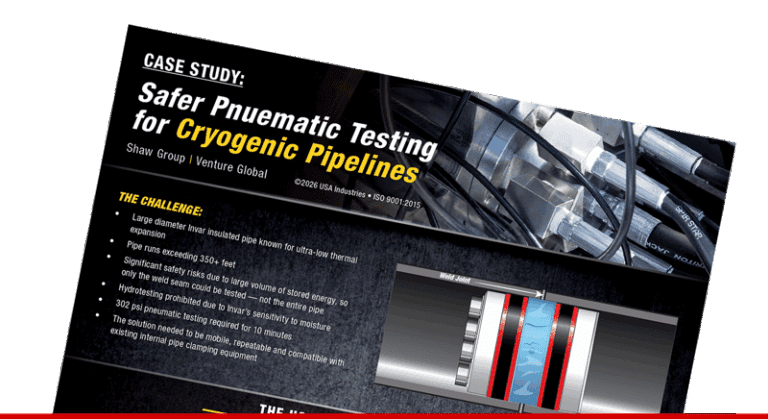

Safer Pneumatic Weld Testing for Large-Diameter Cryogenic Piping

How USA Industries' Custom Rolling Double Block & Bleed Plug Solved a Critical LNG Testing Challenge

PROJECT BACKGROUND

In November 2023, USA Industries was contacted by Shaw Group, supporting Venture Global, regarding a specialized weld testing requirement for a major LNG project.

Shaw Group operates large-scale pipe and module fabrication facilities worldwide, supporting complex energy infrastructure projects. For this LNG application, Shaw was fabricating 28”, 34”, and 40” Invar-insulated pipe, welded together in 35–40 ft sections and assembled into pipe runs exceeding 350 feet.

THE CHALLENGE:

The fabrication process required pneumatic testing of each butt-welded joint before advancing to the next pipe section. However, the project presented multiple constraints:

- Invar piping could not be exposed to moisture, eliminating hydrostatic testing

- Pneumatic testing was required at 302 psi with a 10-minute hold

- Testing the full pipe volume pneumatically posed significant safety risks due to stored energy

- Only the weld seam itself needed to be tested

- The solution needed to integrate with Serimax internal welding clamps already used in Shaw’s automated assembly line

In addition, the testing device had to move efficiently inside the pipe, align precisely with each weld, and support repeatable, production-line testing.

USA INDUSTRIES' SOLUTION

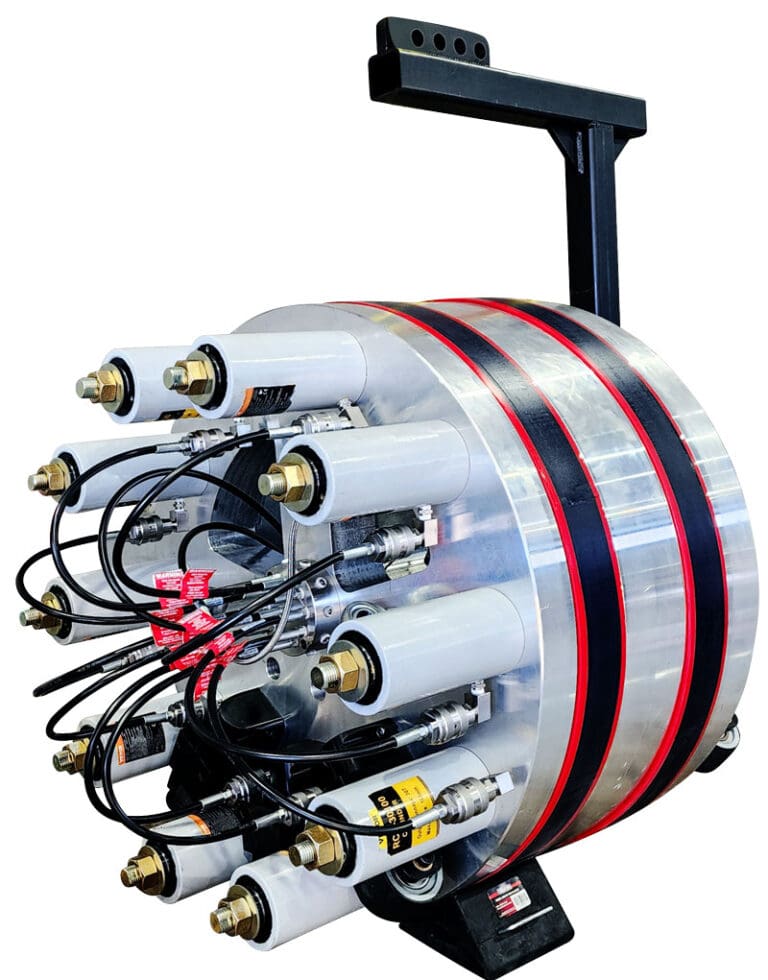

USA Industries proposed a custom Rolling Double Block & Bleed (DBB) Plug engineered specifically to isolate and pneumatically test only the weld zone.

Key Elements of the Solution:

- Dual-seal DBB design to isolate a minimal test volume

- Hydraulically actuated seals for controlled, repeatable expansion

- Integrated internal camera to visually confirm weld location between seals

- Rolling wheel system to minimize drag and allow movement through long pipe runs

- Tie-rod latching system designed to hitch directly onto the Serimax internal welding clamp

This approach significantly reduced stored energy during pneumatic testing, addressing safety concerns while maintaining production efficiency.

THE PROCESS

Shaw Group evaluated several manufacturers to safely pneumatically test large-diameter Invar weld seams while integrating into their existing fabrication workflow, with three ultimately providing solutions aimed at meeting the project's goals.

One other solution offered a technically viable approach; however, it was cost-prohibitive for the required six-month rental period. Other evaluated solutions did not adequately address the need to isolate only the weld zone or integrate directly with Shaw’s production process.

USA Industries’ concept ultimately stood apart by reducing pneumatic risk, supporting localized weld testing, and aligning with Shaw’s automated fabrication requirements.

USAI collaborated closely with Shaw Group and Serimax throughout the development process:

- Iterarive weekly engineering concept discussions, design reviews, technical meetings and customer approvals took place over a three-month period

- Final proposal of a first-of-its-kind rolling DBB configuration was delivered to customer

- Prototype fabrication and validation commenced

- Custom seal specifications required collaboration with Precision Urethane

- Iterative refinements continued based on field feedback

One of the primary challenges was securing approval for a design concept that had never been manufactured before, followed by executing the build under aggressive timelines.

Body Fabrication

Prototype Being Built at USAI

Build Completed

USAI Plug Testing Bunker

Prototype Prepared for Hydrotest

Testing occurred both internally and on-site using pipe spools provided by Shaw. Validation included:

- Internal mobilization through pipe with minimal drag

- Hydraulic seal expansion and pressure integrity verification

- Pneumatic testing of Invar weld seams

- Integration and mobilization while attached to the Serimax clamp

During early field use, USAI addressed real-world issues, including plug stability and hydraulic fitting reliability. The team modified the design in-house, retrofitting hydraulic connections and stabilizing the plug, to ensure dependable operation in production environments.

Customer representatives were on site multiple times throughout testing and validation to confirm performance.

Prototype 1: Initial Onsite Bunker Testing

Prototype 2: Customer Offsite Testing

Prototype 2: Customer Offsite Testing Show with Serimax ID Clamp attached to Placement Torpedo

Prototype 3: Customer Onsite Testing

Final Testing in Louisiana Plant

Following successful field validation:

- USA Industries selected as the approved supplier for the project

- Follow-on order placed for 10 Rolling DBB plugs

- The solution enabled safer, repeatable weld testing without exposing Invar piping to moisture

GOING ABOVE AND BEYOND

USA Industries provided on-site support beyond the original scope, including retrofitting Serimax equipment and supporting startup and operational phases. This hands-on involvement ensured the solution performed reliably under real production conditions.

CONCLUSION

This project demonstrates USA Industries’ ability to deliver custom-engineered solutions where standard tools fall short.

By collaborating closely with Shaw Group, Venture Global, and Serimax, USAI developed a first-of-its-kind Rolling DBB Plug that improved safety, supported production efficiency, and solved a critical testing challenge in LNG Invar pipe fabrication.

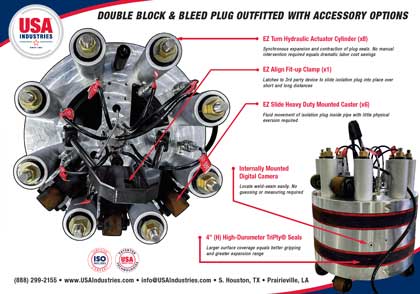

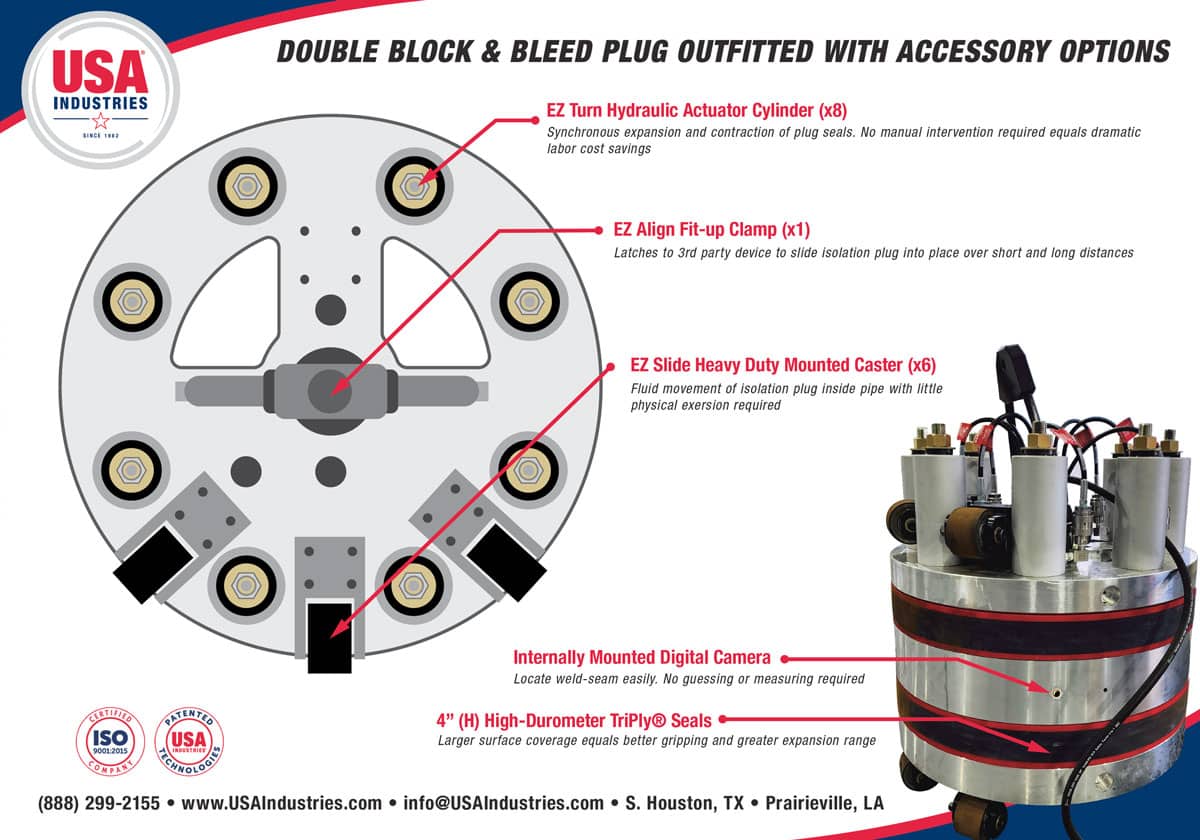

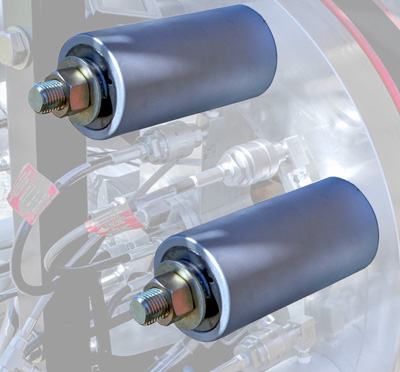

EZ Turn Hydraulic Actuator Cylinders™

Synchronous hydraulic tightening and loosening of seal expansion nuts, which in turn expands and contracts the plug seals. No manual intervention is required, equaling a dramatic time and labor cost savings to you and your project budget.

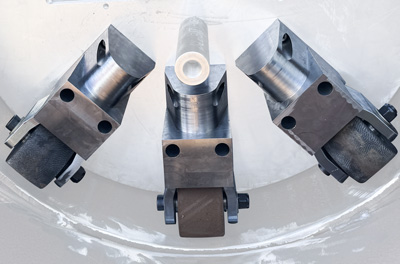

EZ Slide Heavy Duty Mounted Casters™

Casters provide fluid movement of oversized and heavy weighted isolation plug inside the pipe. Consequently, the casters require very little physical exersion to position or reposition pipe plug once seated in the pipe.

EZ Align Fit-up Clamp™

Clamp latches onto 3rd party device in order to slide the oversized and heavy weighted isolation plug into place over short and long distances.

Internally Mounted Digital Camera with Lighting

Internally mounted camera allows you perfectly locate weld-seam. There is no more guessing, or requiring you to measure short and long distances in order to seat the plug properly in place before beginning your project operation.

Ultra-wide Tri-Ply® Seals

The patented multi-durometer Tri-Ply Seal provides a larger surface coverage area over the standard seal, resulting in a greater expansion range, and eliminates seal mushrooming that happens from over torquing the seal expansion nuts.