Custom Machining

USA Industries utilizes advanced CNC machinery and an in-house engineering team to craft parts according to your specific design and material requirements. With the capacity to manufacture millions of custom pieces within short time frames, we are well-equipped to handle substantial projects.

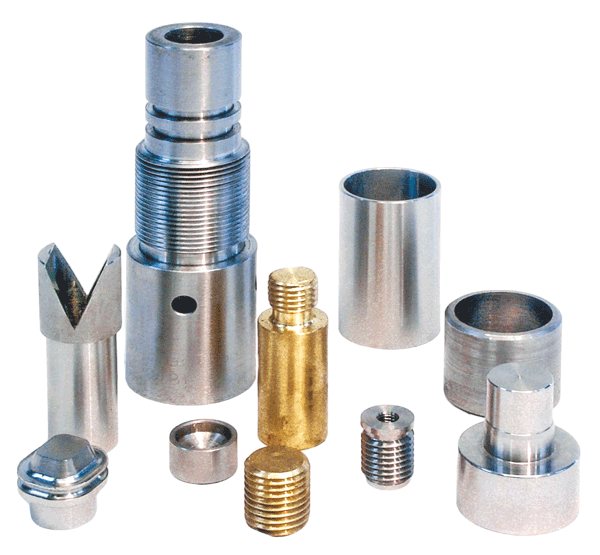

Our lathes can achieve tolerances of +/-1 mils and turn up to 96" OD. Over the past two decades, we have successfully produced custom solutions for diverse industries such as power, chemical, oil & gas, refining, and aerospace. This includes manufacturing various components like pulleys, alignment pins, collars, threading inserts, bolts, collar bolts, specialty flanges for turbines, specialty ferrules, and more.

Types of Parts We Customize:

- Pulleys

- Alignment Pins

- Collars

- Threading Inserts

- Bolts & Collar Bolts

- Specialty Flanges for Turbines

- Specialty Ferrules

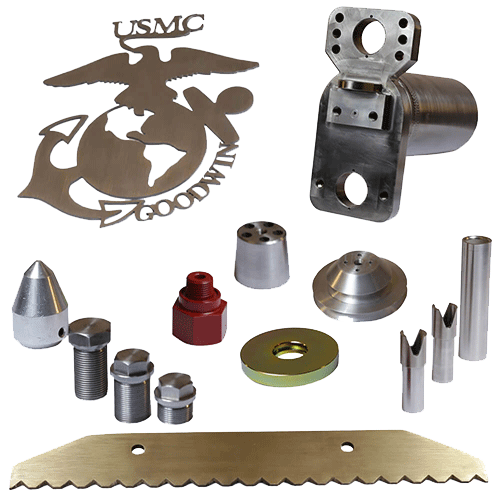

- Aerospace Industry Parts

Machining Capabilities:

- CNC 5 & 4 Axis Mills

- Lathes

- Waterjet

- Plasma & Oxyfuel

- Optical CMMs

- Engine Lathes

- Radial Drills

- Laser Engravers

- Knee Mills & more

We either need a detailed drawing of your item or we need a sample piece to evaluate. As the project progresses, we'll put you in direct contact with our engineering department to send us your files.

We are limited only by the size of the raw material. Our largest machines have a 96" bed, but we have made larger parts.

We accept "emergency" orders and will do all we can to accommodate the lead time needed, but "normal" lead times range from one to four weeks, depending on size, quantity and level of complexity.

We pride ourselves on the ability to tackle almost any job, and we are known for doing what others say is impossible. Give us a try.