USA Industries presents our Exclusive Snap It® Engineered Tube Plugs.

These mechanical tube plugs are ASME PCC-2* compliant, and are simply the best solution for permanently sealing leaking tubes in heat exchangers, boilers, and condensers. Because we are the manufacturer, if we don't already have what you need on the shelf, we can make and ship your tube plugs in days, when competitive distributors can take weeks.

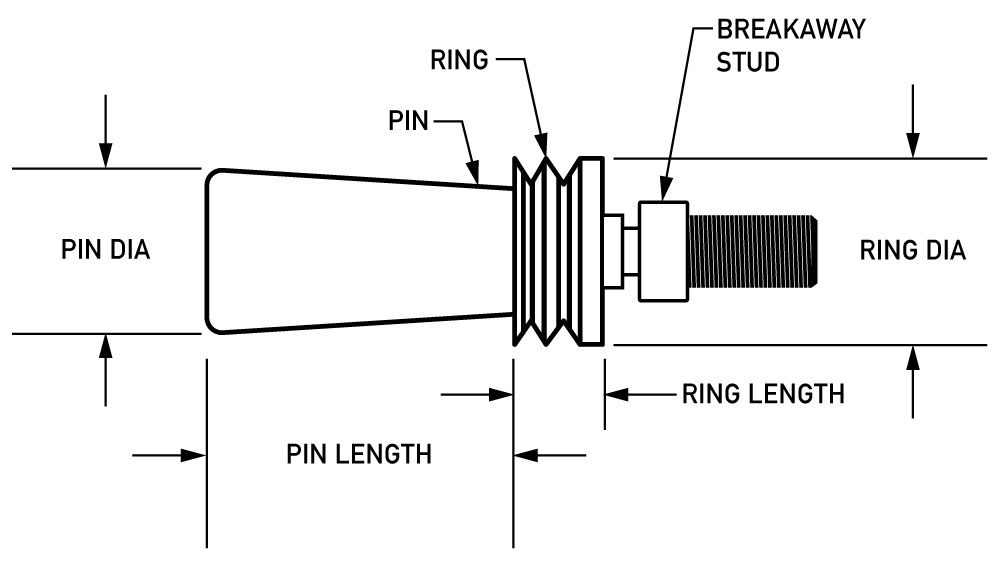

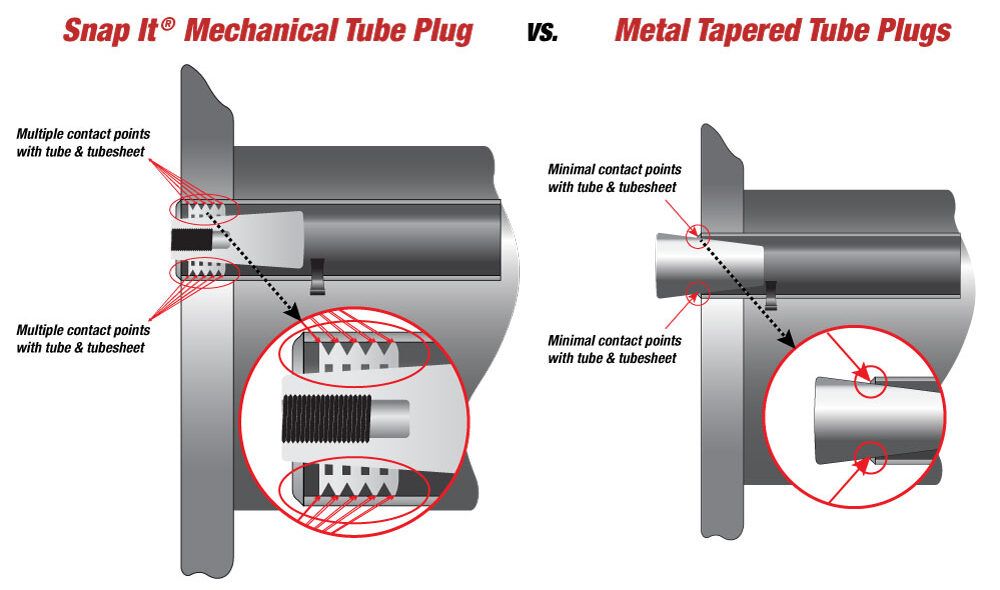

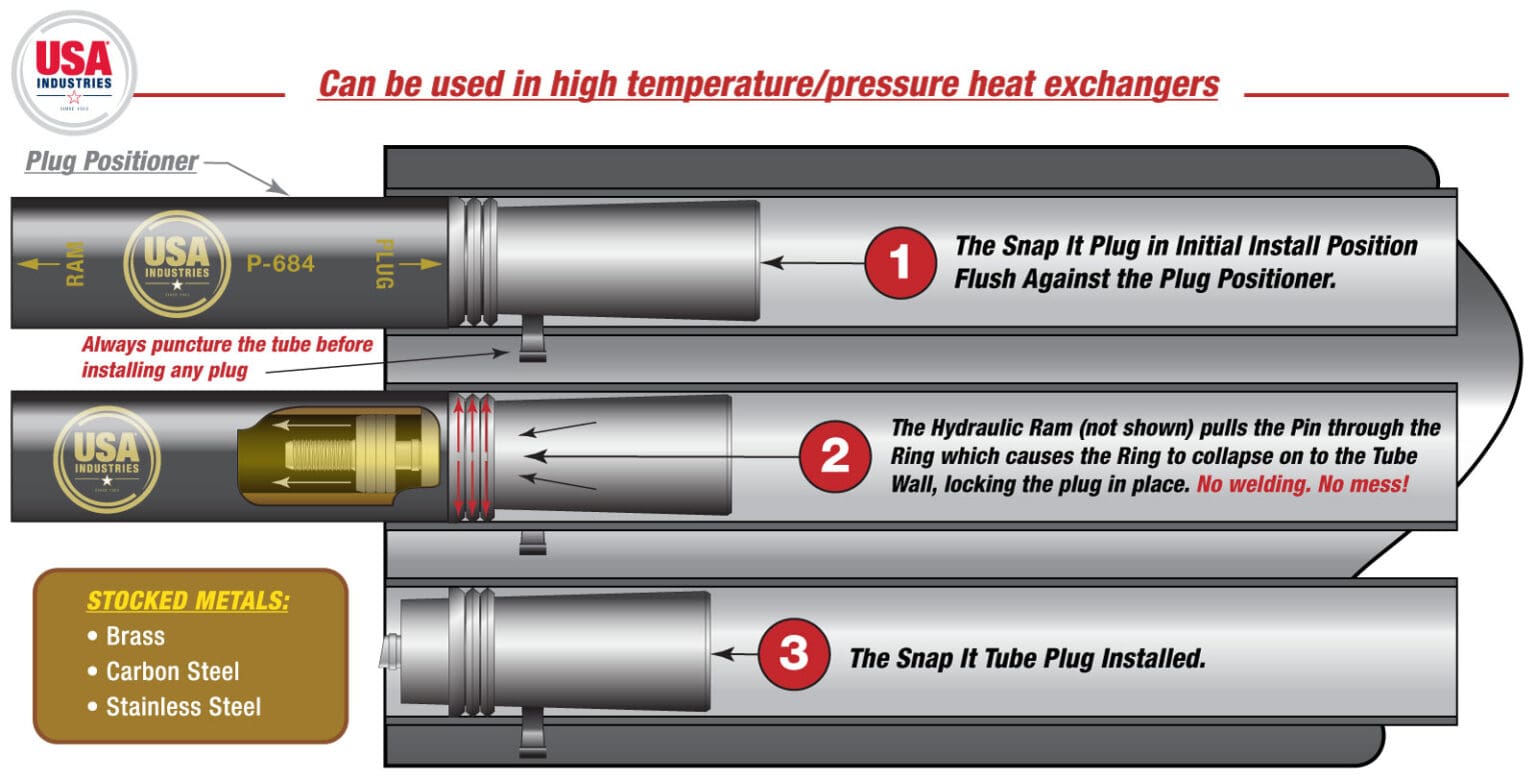

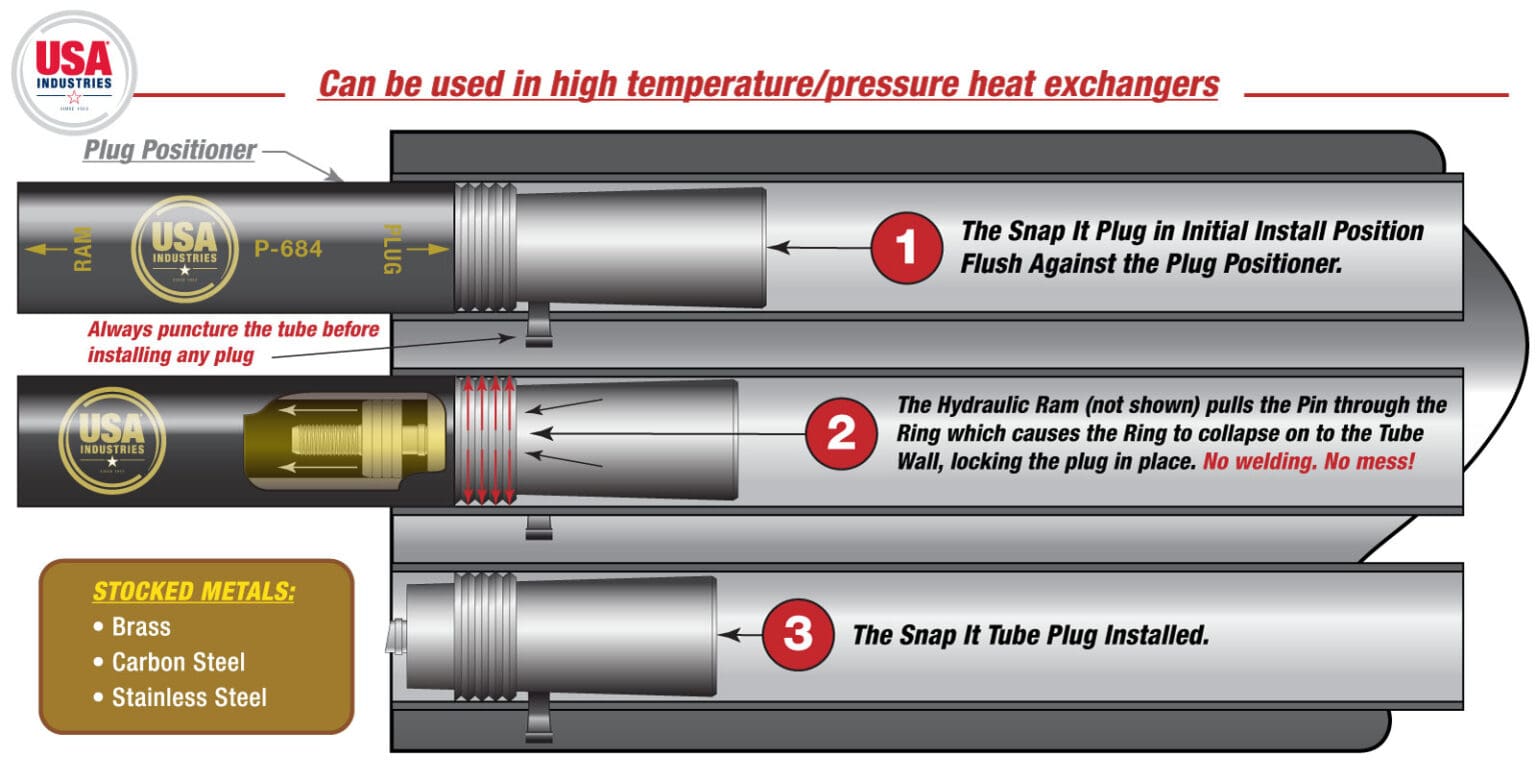

Snap It Engineered Tube Plugs are designed with an external set of serrated rings that ensure a secure helium leak-tight seal, even amidst extreme thermal and pressure changes. Installed hydraulically, Snap It Engineered Tube Plugs ensure consistent, controlled installations in a matter of minutes. Due to the mechanical tube plugs ease of installation, operator fatigue is dramatically reduced, while safeguarding tubes, tubesheets, and adjacent components structural integrity. Snap It Engineered Tube Plugs deliver pressure ratings up to 7,000 PSID.

SNAP IT ENGINEERED TUBE PLUG FEATURES:

- Ideal for medium and high-pressure applications

- Maximum Pressure: up to 7,000 PSI (Sr. models)

- Requires NO welding

- NO damage to tubesheet

- Materials: Stainless, Carbon Steel, Brass, Titanium, and more

- Lot tested and strict quality assurance controls

- ASME PCC-2 compliant

BENEFITS FOR USING SNAP IT ENGINEERED TUBE PLUGS:

Heat Exchanger Tube Plugs enhance safety by preventing leaks that could cause fluid mixing or pressure loss. Use USA Industries Snap It Engineered Tube Plugs to ensure maximum safety and reliability when plugging heat exchanger, boiler, and condenser tubes.

SNAP IT INSTALLATION AND REMOVAL KIT ACCESSORIES:

We offer a complete Snap It Installation and Removal Kit for rental or purchase which includes tube brushes, hydraulic ram, pull rod assembly, channel head pull rod assemblies, extension sets, and plug removal tools.

What is ASME PCC-2?

*ASME PCC-2 stands for the American Society of Mechanical Engineers (ASME) Post Construction Committee 2. It is a standard developed to provide guidelines and procedures for the repair of pressure equipment, including vessels, piping, and related components, after they have been constructed and put into service. ASME PCC-2 covers various aspects of repair, including design, fabrication, inspection, and testing, and it offers recommendations for both temporary and permanent repairs depending on the situation. The standard is widely used in industries where pressure equipment is prevalent, such as petrochemical, oil and gas, power generation, and manufacturing.

Copyright © 2022 by THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

Snap It Plugs must be installed exclusively within the rolled section of the tubesheet. If the tubes are not rolled into the tubesheet, contact USA Industries at 1-888-299-2155 for guidance before proceeding further. Before installation, eliminate any scale and pitting using USA Industries’ Snap It Brushes. Additionally, ensure that any weld droop is removed prior to plug installation.

Snap It® Plug Installation & Removal Instructional Videos

1 Introducting USA Industries Snap It Kit

2 Assembly of USA Industries Snap It Kit Tools & Accessories

3 Piercing and Brushing the Tube Using USA Industries Snap It Kit Tools and Accessories

4 Installing USA Industries Exclusive Snap It® Jr. Tube Plug

5 Removing USA Industries Snap It® Tube Plug from the Heat Exchanger

6 USA Industries Snap It® Tube Plug Far End Plugging Procedures