Bleed Rings

Drain Piping | Bleed Valves

Money.

Rent.

Bleed Ring

(Drip Ring) Specs:

| Sizes: | 1/2" - 14" (custom sizes available) |

| Customization Options: | Material | Size | Tap Connection Types & Sizes | Gasket Type | # of Ports |

| ASME | ANSI Standards Conformations: | B16.5 & B16.20 for raised face and ring type joint (RTJ) dimensions and tolerances |

| Materials Origin: | USA |

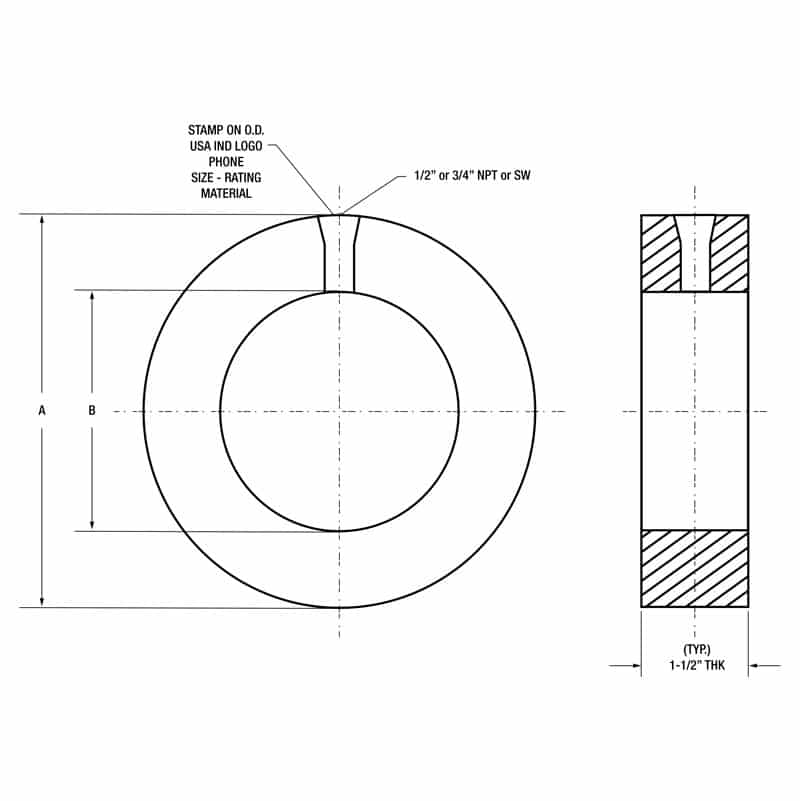

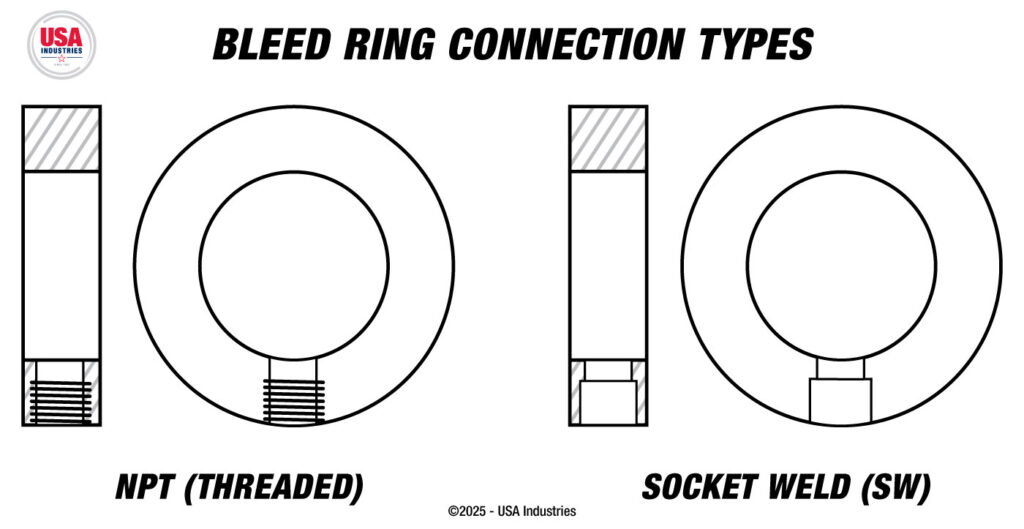

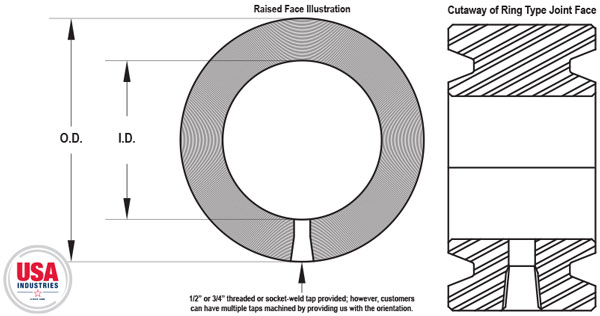

| Connection Type Options: | 1/2" or 3/4" Threaded or Socket-Weld |

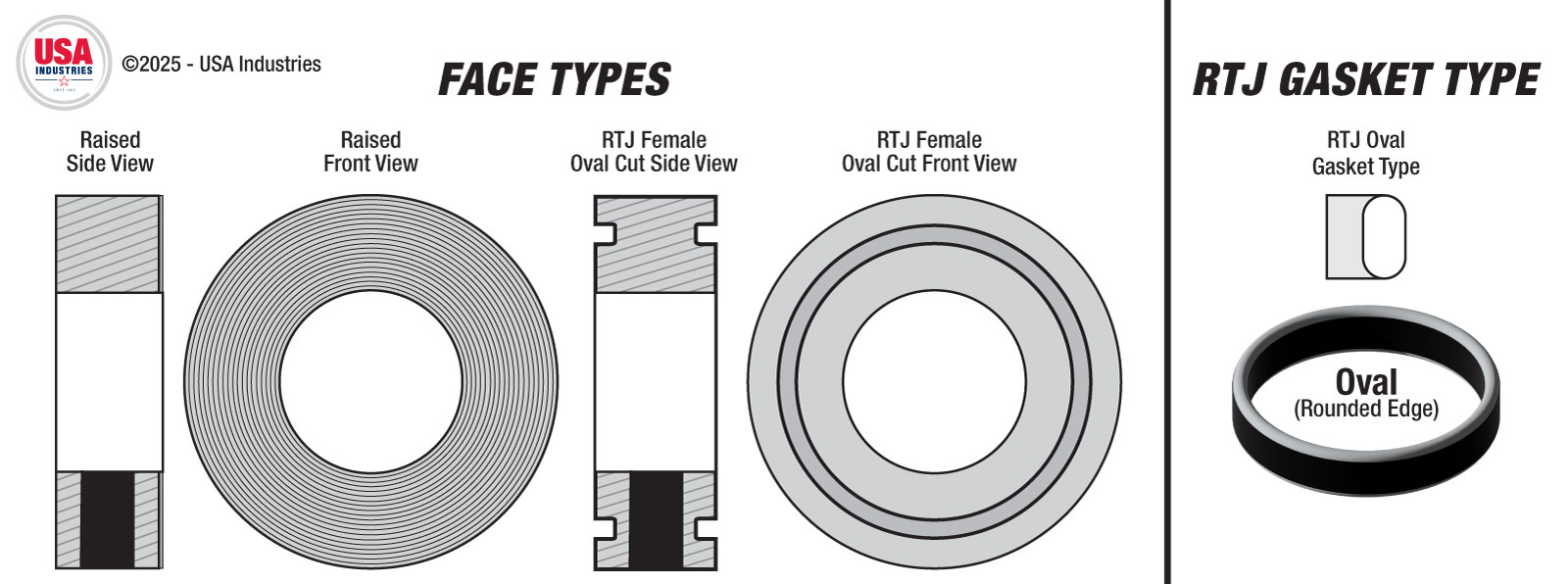

| Face Options: | Raised (125-250 RMS) | RTJ Male or Female |

| Finish: | Carbon steel plate products receive one coat of black lacquer unless alternative specifications are provided |

| NSF ANSI/CAN 61 Certification: | NSF ANSI/CAN 61 certification applies exclusively to our stainless steel products |

- Standard Ring Joints (RJ) feature female oval ring grooves (male joints are available upon request)

- Same-day local shipping/delivery available in Texas and Lousiana

For custom requirements, USA Industries offers tailored solutions under our ISO 9001:2015 quality-assurance program.

To Order Call:

(800) 456-8721

Specify:

- Flange Rating (150#, 300#, 600#, 900#, 1500#, 2500#)

- Size (1/2" - 96")

- Number, Size & Type of Bleed Holes - Threaded or Socket Weld

- Steel Material Type (Carbon, Stainless - 304, 316, Other)

- Gasket Surface Type

- Quantity Needed

- Necessary Delivery Date

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Color-Coded Handles

Easy rating identification with color-coded handle system.

100% USA Materials

All raw materials sourced from American mills.

Blind

Processing

What separates USA Industries blinds from the competition — built into every piece.

Why Our Blinds Are Different

We are the actual manufacturer, not just a reseller. Since 1982, using advanced CNC plasma and waterjet machines, each blind is crafted with engineered symmetry, clean edges, fresh paint (carbon steel), marked or stamped, and color-coded handles for easy flange rating identification. Also, our blind solutions are crafted from top-grade, American milled alloys, including carbon steel, stainless steel, and other specialized materials known for their strength, durability, and corrosion resistance.

Moreover, unlike others who may claim this, USA Industries has the largest stock for immediate delivery and in-house production.

| Bleed Ring Dimensions | ||||||

|---|---|---|---|---|---|---|

| Line Size | O.D. ▾ | I.D. | ||||

| 150# | 300# | 600# | 900# | 1500# | ||

PRIMARY USES:

- Pressure Relief: safely releases excess pressure from pipelines or vessels caused by thermal expansion, equipment malfunctions, or process breakdowns, preventing system damage.

- System Protection: helps maintain safe pressure levels, safeguarding equipment, personnel, and the environment from overpressurization risks.

- Fluid Drainage & Sampling: provides access points for draining fluids or collecting samples for analysis, quality control, or maintenance without system depressurization.

- Operational Efficiency: enables maintenance and monitoring with minimal downtime, reducing disruptions to production processes.

Bleed Ring 3D Product Rotation

USA Industries NSF ANSI/CAN 61 certification applies exclusively to our stainless steel products.

NSF/ANSI 61 is the NSF standard ensures that any materials, coatings, or products that come into contact with drinking water do not leach harmful contaminants into the water at unsafe levels.

NSF 61 Covers:

- Pipes & fittings (metal, plastic, concrete, etc.)

- Valves & gaskets

- Meters & water treatment devices

- Coatings, linings, sealants, solders

- Any materials that touch drinking water in distribution systems

It Tests For:

- Leaching of lead, arsenic, mercury, and other heavy metals

- Leaching of organic contaminants (e.g., solvents, plasticizers)

- Other harmful chemicals that might migrate from the material into water

Why It Matters:

- It’s a regulatory requirement in most U.S. states and Canadian provinces for products used in public water systems.

- Products with NSF/ANSI 61 certification give assurance that they are safe for use with potable (drinking) water.

Frequently Asked Questions

Yes, multiple NPT ports can be added upon request.

Yes, we can add a larger tap, but the thickness may need to be adjusted to accommodate this.

They are typically 1.5" thick, but can be made in other thicknesses upon request. Your studs will need to accommodate the space of the bleed ring and flanges.

Yes. We regularly provide Bleed Ring / Drip Ring / Vent Ring with socket weld taps.

Yes, we can custom manufacture our bleed rings the way you require.

We primarily manufacture our bleed rings in 304 and 316 stainless steel, but we can make them in any material you need.

Yes, as the manufacturer we can customize any of our products to your exact specifications.

Absolutely! A large bleed ring is not a problem. We can go up to 80" O.D. on our lathes, and can customize solutions for even larger diameters when needed. Let us know what you need, and we'll be happy to manufacture it for you.