Non-Gripping

Double Block & Bleed

Money.

Rent.

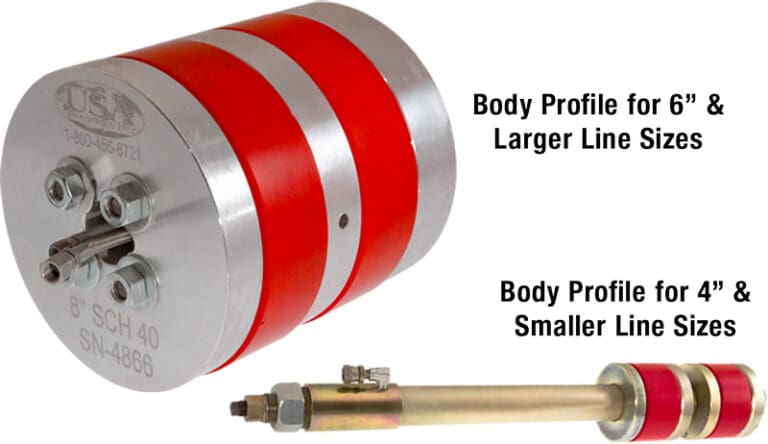

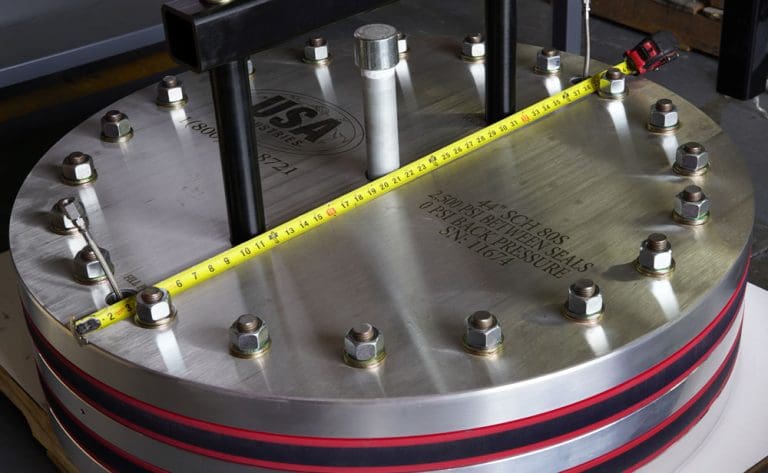

Non-Gripping Double Block and Bleed Specs:

- Standard Size Range: 3/4" to 24" NPS; larger sizes available upon request

- Working Pressure: Up to 2,500 PSI (172.4 Bar) between seals

- Body Construction: Lightweight aluminum/steel assembly for strength and portability

- Seal Material: High-performance urethane seals

- Portability: Compact, easy to position, and designed for quick deployment

- Pipe Protection: Will not damage internal pipe walls during installation or removal

- Efficiency: Reduces repair and weld-testing time and associated labor costs

- Purge Reduction: Minimizes purge gas usage and waste generation

- Water Usage: Requires less than one gallon of water, reducing fill time, waste, and treatment costs

- Testing Requirements: Only a small test volume needed—compatible with simple hand pump operation

- Safety: Built-in safety factor helps reduce NDE requirements

- Monitoring Capability: Allows monitoring of isolation zone and upstream pressure to prevent backpressure during testing

Optional Additional Technical Points

- Seal Redundancy: Dual-seal configuration provides enhanced isolation integrity

- Pressure Relief Port: Bleed/vent port to safely remove trapped pressure

- Application Flexibility: Effective for hydrostatic testing, weld isolation, and temporary line blocking in maintenance environments

To Order Call: (800) 456-8721 — Specify:

- Size

- Pipe Schedule

- Quantity Needed

- Rental or Purchase

- Necessary Delivery Date

ISOLATION/TEST PLUGS VS. WELDING END-CAPS

Isolation/Test plugs deliver faster turnarounds, lower costs, improved safety, and greater flexibility than welding end caps on pipe spools—transforming pressure testing from a bottleneck into a streamlined operation.

THE COMPARISON

GSST Isolation / Test Plugs

RecommendedWelding End-Caps

Legacy MethodWHY PLUGS WIN

Faster Turnarounds

Eliminate welding and grinding time. Go from installation to pressure testing in minutes, not hours—keeping your project schedule on track.

Lower Total Cost

Reusable plugs replace single-use caps, welder labor, consumables, and post-weld inspections. The ROI is immediate and compounding.

Improved Safety

Zero hot work means no fire watches, no arc flash risk, no fume exposure, and no hot work permits. A fundamentally safer process.

Greater Flexibility

Quickly adapt to changing test configurations. Reposition plugs across different spools and pipe sizes without rework or waste.

THE BOTTOM LINE

Isolation/Test plugs transform pressure testing from a bottleneck into a streamlined operation—delivering speed, savings, safety, and flexibility that welding end-caps simply cannot match.

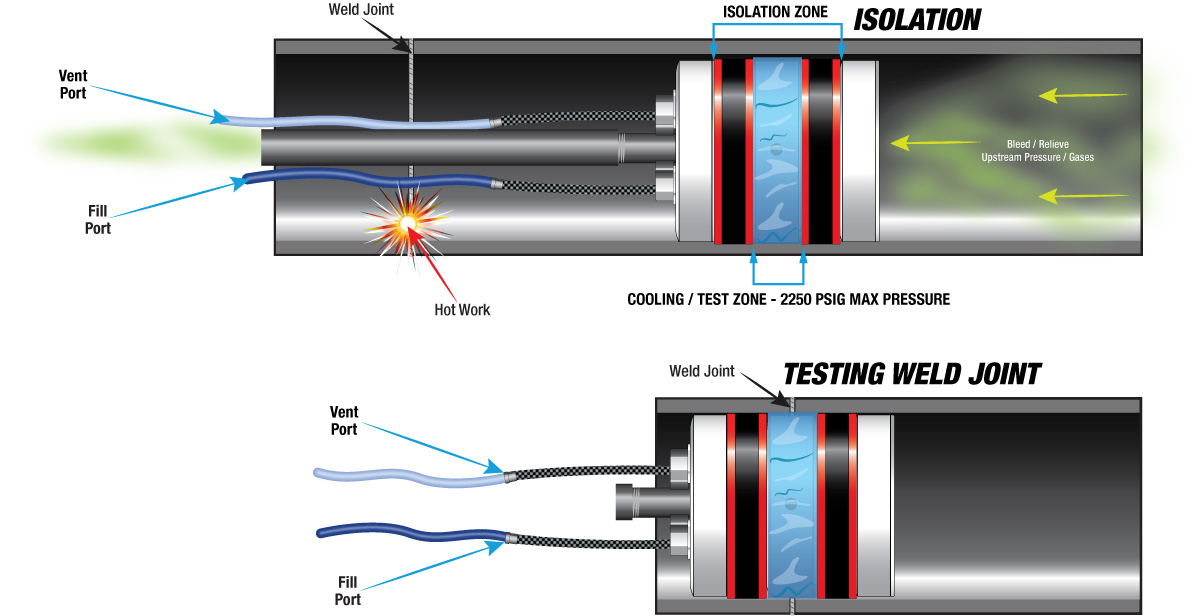

USA Industries' Double Block & Bleed (DBB) pipe plug is built with two separate sealing areas that allow the user to positively isolate upstream gases from internal piping. As a result of this design, it makes performing modifications, repairs and hot work much safer, quicker and easier. The Double Block & Bleed plug also has a vent between the compression seals that lets the user verify the seals' integrity and pressure test the hydrotest welds by positioning the weld between the two seals.

HOW THE STANDARD DOUBLE BLOCK & BLEED WORKS

After determining pipe and schedule size:

- Install DBB plug upstream of "hot work" area

- Expand seals by tightening compression nut(s)

- Inject inert gas or water between seals (isolation zone) and pressurize

- Monitor isolation zone and upstream pressure during "hot work"

- After weld cools release pressure and seal, reposition isolation zone over weld area

- Pressurize isolation zone (up to 2,500 psi (172.4 Bar))

In addition to making hot work safer, quicker and easier, USA Industries manufactures our isolation and test plugs under a strict quality assurance system. All plugs are certified to ISO 9001 standards.

A Critical Reminder: Conducting pressure testing poses significant hazards, demanding strict adherence to safety protocols. Ensure all connections, valves, flanges, and fittings are suitable for pressure testing. Verify the compatibility of line ID & Plug Range. Most importantly, never position yourself in front of a test plug or enclosure during testing. Discharge from a plug during testing could result in severe injury or fatality.

Technical Documentation

Frequently Asked Questions

Yes! The Double Block & Bleed plug has a vent in between the compression seals that lets you to verify the seals integrity and pressure test / hydrotest welds by positioning the weld between the two seals.

The DBB plug operates in working pressures to 2,250 PSI (155.2 Bar). Use it to monitor isolation zone and upstream pressure, preventing backpressure build-up during tests.

The sealing material is made of urethane.

Our standard urethane seals continuous operating temperature are rated at 180°. We also offer high-temperature seals upon request.

Yes, we have several extended reach sizes available. Just let us know what reach you need.

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Engineering Innovation

Precision-Engineered Industrial Solutions — Delivered Fast!

100% USA Materials

All raw materials sourced from American mills.