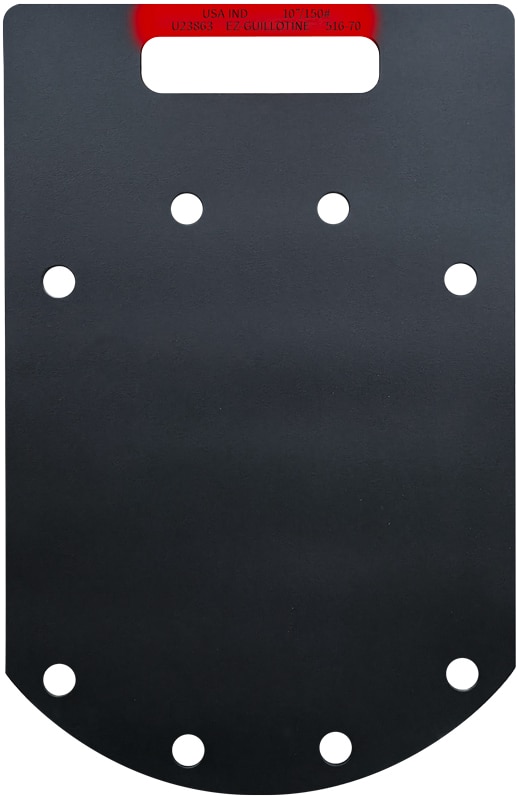

EZ Guillotine™

PSV Isolation Blind

The Flare

Header Side

EZ GUILLOTINE BLIND PRODUCT DESCRIPTION

A pipe that is fully open releases an enormous amount of gas and vapor, even at low pressures, into the surrounding area. If an accidental spark sets off the vapor cloud, devastating results will occur. The EZ Guillotine slip blind greatly minimizes this exposure to a few seconds of partially open exposure. This blind is the only one on the market for isolating the flare header side of a pressure safety valve (PSV).

Installation of this specialty blind is as easy as slipping the Guillotine blind in between the header flange. After installed, utilize cap screws to secure the Guillotine blind, remove the PSV, and use remaining flange bolts to install a blind flange behind the Guillotine.

EZ-GUILLOTINE PRODUCT FEATURES:

- The only blind on the market designed specifically for PSVs

- Installs easily in just minutes with existing cap screws

- Unique design decreases risk of injury during removal of valve

- Available in isolation, hydrotest or custom thicknesses

Request a product demo of the EZ Guillotine Slip Blind below and one of our product specialists will come out to your facility to show you the benefits of this specialty blind.

We constantly innovate new piping isolation solutions and enhance our products. We have two options for blinds: the patented EZ Lock Blind Rack® and our custom industrial blind solutions. Our custom solutions include EZ Vent-Purge®, EZ Vent®, EZ Purge®, and EZ Guillotine™ blinds. These options can help you save time and money.

NEED SAFE & SECURE PADDLE BLIND STORAGE?

Check Out USA Industries' Patented EZ Lock Blind Rack®!

Paddle Blinds, Specialty Slip Blinds & Blind Flanges

Frequently Asked Questions

EZ Guillotine blinds are used to provide an isolation source on the downstream side, commonly known as the flare header side, of a PSV prior to removal of the PSV for repair. The EZ Guillotine is not rated to hold more than 1-2 pounds of pressure. The purpose is to shield the technician removing the PSV from unnecessary exposure to hydrocarbons or whatever is in the open downstream side pipe. A blind flange is installed over the EZ Guillotine after the PSV has been removed to safely secure the seal against any pressure that might occur.

Customers have typically requested them to be 1/4" thick, but we can easily make thicker blinds upon request!

When the upstream side of a PSV has been isolated and the pressure has been released, remove all the bolts that would impede the EZ Guillotine blind and fully loosen the others on the downstream side. Next slip the EZ Guillotine blind and gasket between the PSV and the unbolted flange. Using the proper size hex bolts and washers, attach the EZ Guillotine to the downstream flange and tighten until snug. Remove the PSV fully and place a blind flange over the EZ Guillotine. Finally, using the original stud bolts, secure all available holes and tighten until the EZ Guillotine is held securely in place by the blind flange. You're done! Simply leave the EZ Guillotine hex bolts in place, and upon reinstallation of the PSV reverse the procedure.

Customers use the EZ Guillotine blind to increase the safety of the technicians, and reduce the release of hydrocarbons or chemicals while removing a PSV when the pressure in the flare header is low enough to perform this - roughly zero to one pound. Even at these low pressures, an open-ended pipe can release an enormous amount of vapor into the surrounding area very rapidly. In this situation you have the possibility of a spark setting off the vapor cloud and a fire occuring. The EZ Guillotine slip blind greatly minimizes this longer, fully open exposure to a few seconds, partially open exposure when installed efficiently and correctly. After removal of the PSV a blind flange is installed over the EZ Guillotine to hold everything in place against any intermittent pressure.

Bottom Line...Increased Safety, Decreased Environmental Impact...Win/Win!!!

The EZ Guillotine blind is manufactured just wide enough to be installed with the side bolts of the PSV still in place. This increases safety for the technician and the environment!

Typically no. However, we can supply gaskets or seals to you with your order upon request. It is recommended you affix a paper gasket to the EZ Guillotine on the flare header side using adhesive and let it "set" prior to installing the EZ Guillotine.

If requested we can make the EZ Guillotine so that single or multiple O-Rings can be installed on the sealing surface.

The same way many of our products are developed and come to market. A customer had a need, and they asked us to help come up with a design. As a custom machine shop, we're always looking for new, inventive solutions to our customers' every day problems. Got a problem of your own? Reach out and let us know!