EZ Purge® Paddle Blind

Ensure safe purging and equipment protection – rental and purchase options available.

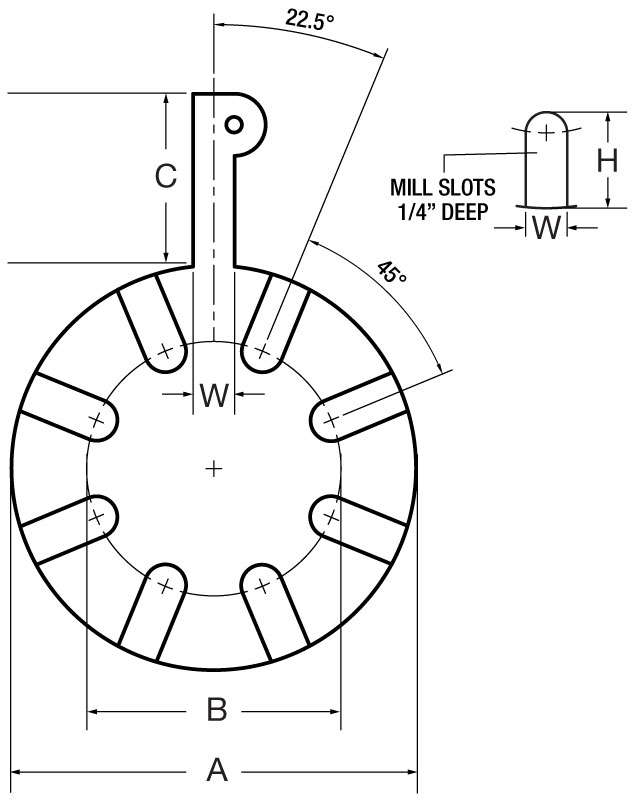

EZ Purge Slip Blind Specs:

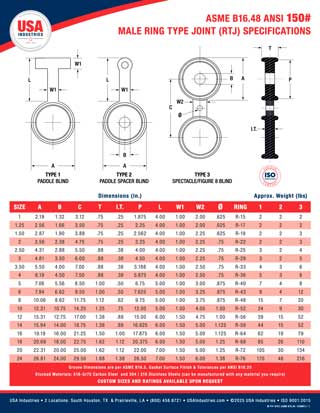

| Sizes: | 1/2" - 96" |

| Rating Classes: | 150# • 300# • 600# • 900# • 1500# • 2500# |

| Blind Thickness: | Standard blind: ½" thick with ¼" deep channel, widths of ¾", 1", or 1½" depending on size |

| Stocked Alloys: | 516-Gr70 CS • 304/316 SS (Any Available Alloy) |

| Materials Origin: | USA |

| Coating Options: | Various |

| "P" Cut Handle: | Specialty handle designates "PURGE" for easy inline recognition |

| Gasket-to-Purge Area Ratio: | ~.5 (ensures seal) |

To Order Call: (800) 456-8721 — Specify:

- Flange Rating (150#, 300#, 600#, 900#, 1500#, 2500#)

- Size (1/2" - 96")

- Face Type (Mill, Serrated)

- Steel Material Type (Carbon, Stainless - 304, 316, Other)

- Quantity Needed

- Necessary Delivery Date

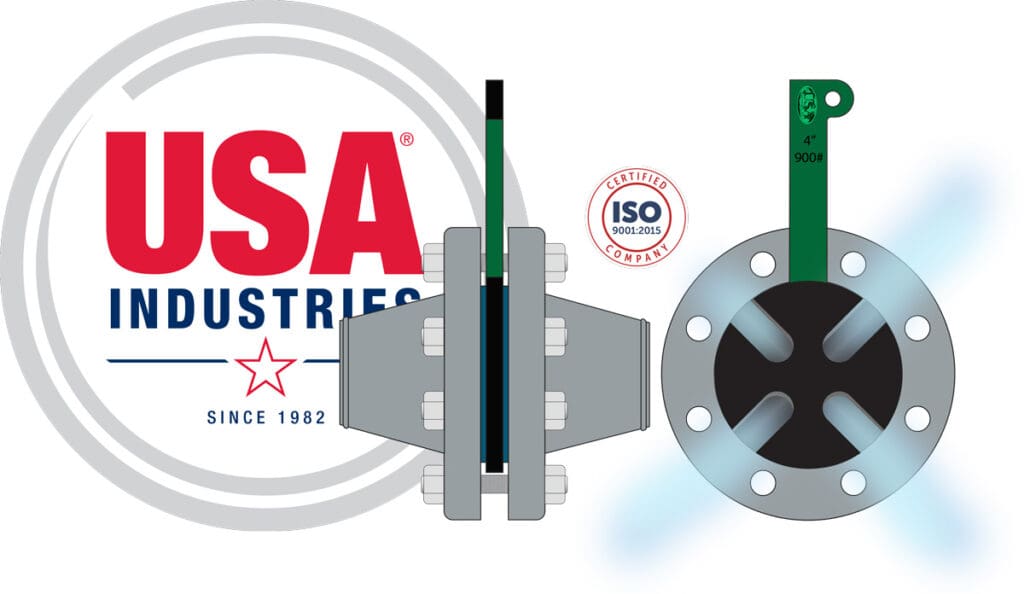

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Color-Coded Handles

Easy rating identification with color-coded handle system.

100% USA Materials

All raw materials sourced from American mills.

USA Industries Blind Processing

See what makes our blinds different from the competition

Manufactured In-House

Complete control over quality and lead times

U.S. Produced Steel

All raw materials from American mills

PMI All Raw Materials

Positive material identification on every piece

Waterjet & Plasma Cut Materials

Precision cutting for exact specifications

Cut Deburring

Smooth, safe edges on every blind

QC Verified Cuts

Quality control inspection on all products

Stamped with Blind Specs

Clear identification of ratings and specifications

Color-Coded by Class Rating

Instant visual identification system

Painted (Carbon Steel)

Protected against corrosion

Order Verification

Double-checked before shipment

NSF ANSI/CAN 61 Certified

For Stainless Steel Blinds

Why Our Blinds Are Different

We are the actual manufacturer, not just a reseller. Since 1982, using advanced CNC plasma and waterjet machines, each blind is crafted with perfect symmetry, clean edges, fresh paint, marked or stamped, and color-coded handles for easy flange rating identification. Also, our blind solutions are crafted from top-grade alloys, including carbon steel, stainless steel, and other specialized materials known for their strength, durability, and corrosion resistance.

Moreover, unlike others who may claim this, USA Industries has the largest stock for immediate delivery and in-house production.

Need Blind Storage?

Protect Your 1/2"–14" Paddle Blinds with the Patented EZ Lock Blind Rack®

Rent or Buy the Patented EZ Lock Blind Rack from the Industry Leader in Blind Storage Solutions!

- Safely store and organize paddle and spectacle blinds

- Stackable design for 16" and larger blinds

- Rental and purchase options available

- Reduces handling damage and improves organization

USA Industries' EZ Purge Slip Blind offers operators a safe and modern alternative to the outdated line purging practices involving a slip blind and spacers, which poses safety risks and equipment damage. The EZ Purge slip blind creates a "standoff" area at the flange site for line purging. It seals evenly, preventing damage to flange gasket surfaces caused by wedges, tubing, or other metals used to create space.

A Purge Blind enhances safety and system integrity by:

- Isolating Pipeline Sections: Prevents leaks, spills, and contamination during maintenance.

- Facilitating Welding: Creates a controlled environment for high-quality welds using inert gases.

- Maintaining System Integrity: Allows inspections and repairs without disrupting operations.

- Ensuring Accurate Pressure Testing: Seals sections to prevent leaks and pressure loss.

- Regulatory Compliance: Supports adherence to safety and environmental standards.

Paddle Blinds, Specialty Slip Blinds & Blind Flanges

Frequently Asked Questions

Our standard thickness is 1/2" with 1/4" milled slots.

We can manufacture hydrotest EZ Purge blinds that will withstand hydrotesting, but our standard blinds are designed for isolation only. Please let us know at the time you're ordering, and we can increase the thickness of the non-purged side to withstand hydrotesting.

Yes, but if you want them much deeper, we will suggest the total thickness of the blind to be increased.

Yes, what you're asking for is our EZ Vent-Purge® blind that combines both the EZ Vent and EZ Purge benefits into one specialty blind.

Carbon steel blind handles are painted to match the standard flange rating colors. All of our slip blinds are indent marked and polished to smooth edges.

We have designed our EZ Purge blind to have an effective purge area of 50% to prevent damage of the gasket surface.

Yes. Our proprietary design allows you use this blind with or without a gasket on the purge side. This will not affect the amount of purge flow.

Yes. We can do both machined 125-250 rms finishes and RTJ male or female surfaces upon request.