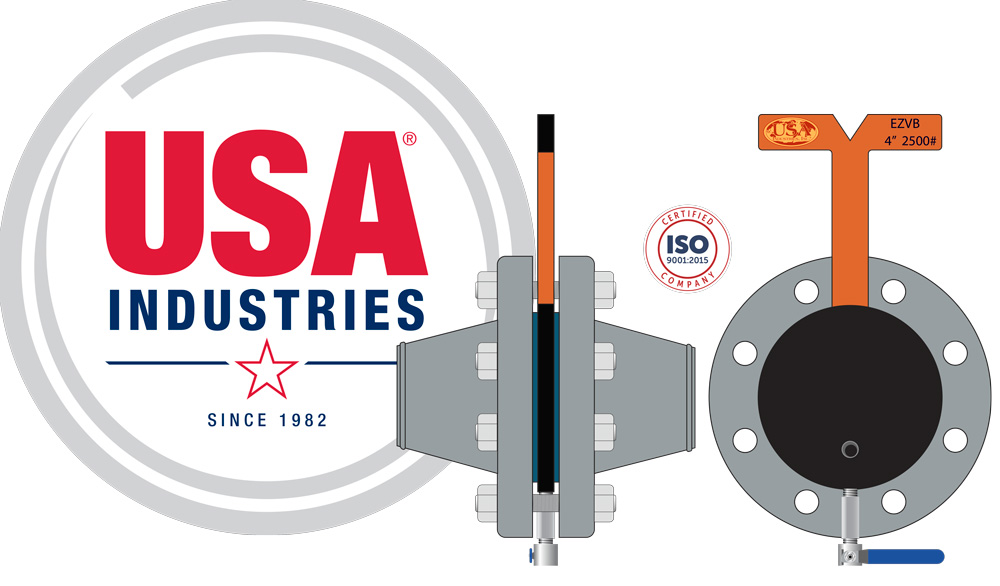

EZ Vent® Slip Blind

Protect your operations with vented paddle blinds – flexible rental and purchase options available.

EZ VENT SLIP BLIND SPECS:

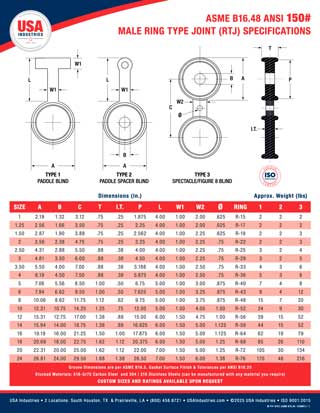

| Sizes: | 1/2" - 96" |

| Blind Types: | Paddle or Spectacle Blind |

| Rating Option: | Can Be Rated (with additional thickness for vent) |

| Stocked Alloys: | 516-Gr70 CS • 304/316 SS (Any Available Alloy) |

| Materials Origin: | USA |

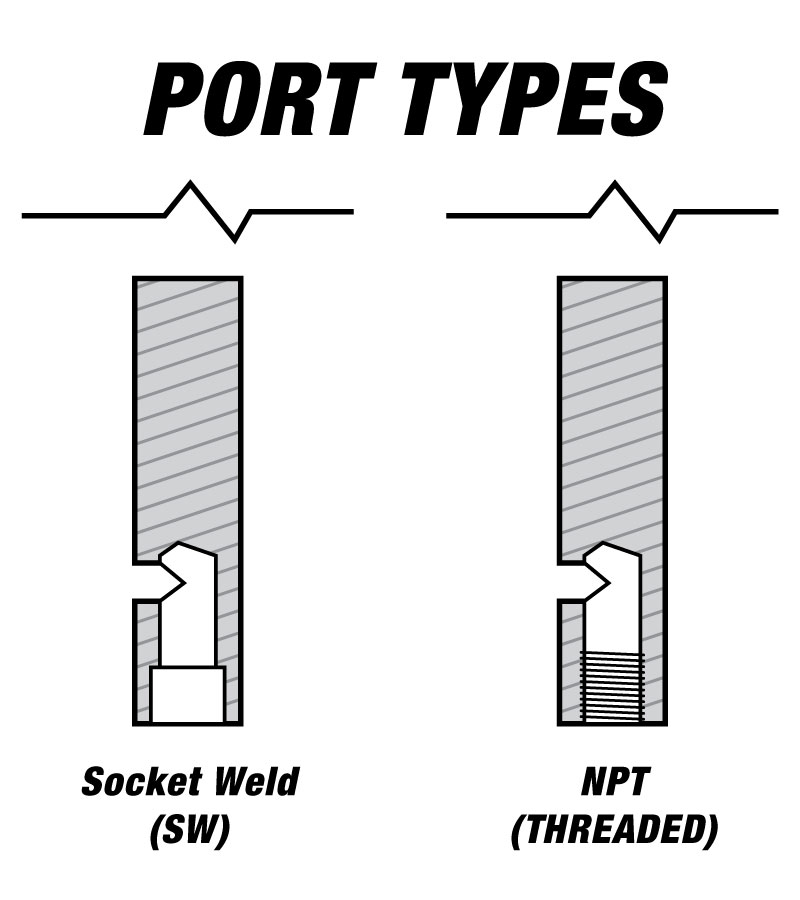

| Port Options: | NPT or SW |

| Multiple Ports Can Be Added (venting one or both sides) | |

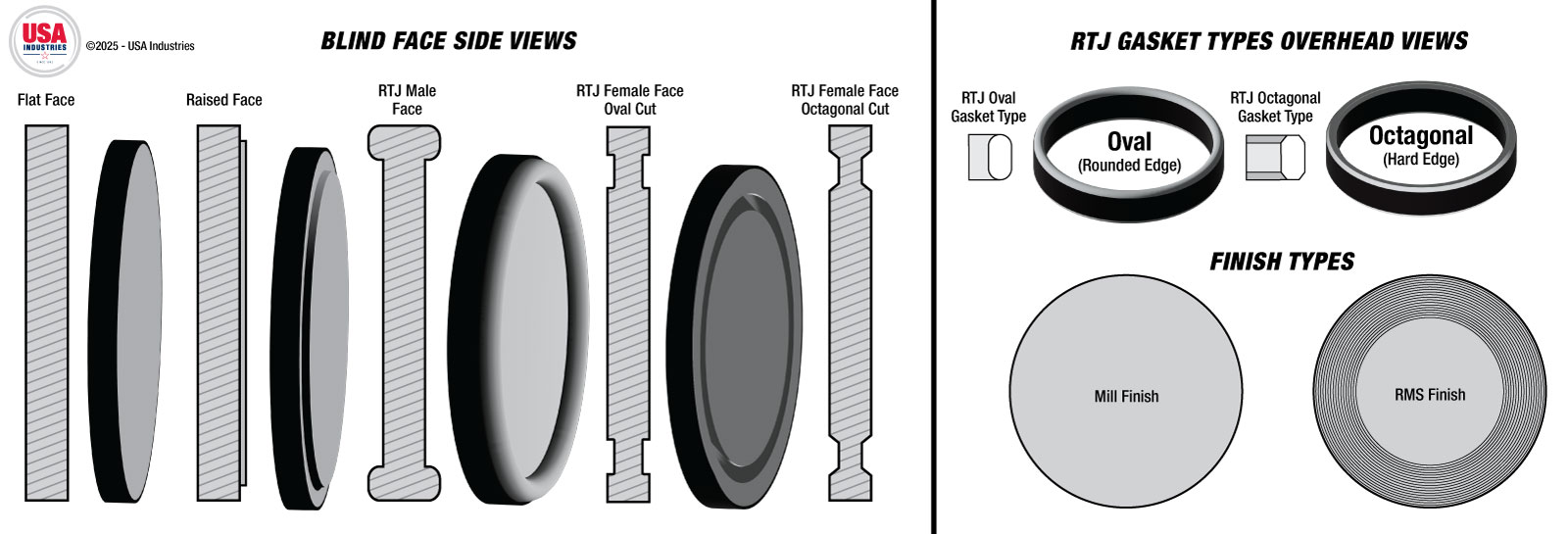

| Face Options: | Flat • RTJ Male • RTJ Female |

| Gasket Types: | Octagonal • Oval |

| Finish Options: | Serrated (125/250 RMS) • Mill |

| Coating Options: | Various |

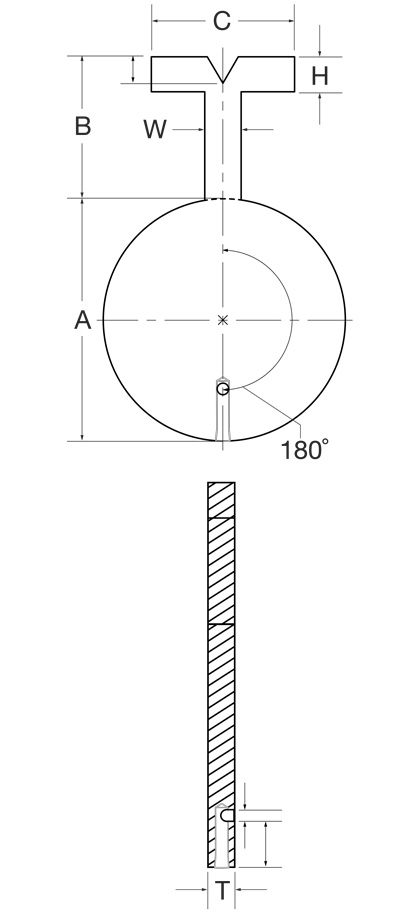

| "V" Notched Handle: | Specialty handle designates "VENT" for easy inline recognition |

- Easy identifiable rating specific coloring, stamped markings, specialty handles, and smooth grounded edges

- Can be made to your customized specifications

- Same-day local shipping/delivery available in Texas and Lousiana

For custom requirements, USA Industries offers tailored solutions under our ISO 9001:2015 quality-assurance program.

USA Industries Blind Processing

| Manufactured In-House | X |

| U.S. Produced Steel | X |

| PMI All Raw Materials | X |

| Waterjet & Plasma Cut Materials | X |

| Cut Deburring | X |

| QC Verified Cuts | X |

| Stamped with Blind Specs | X |

| Color-Coded by Class Rating | X |

| Painted (Carbon Steel) | X |

| Order Verification | X |

To Order Call: (800) 456-8721 — Specify:

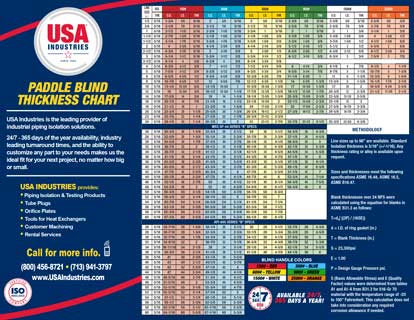

- Flange Rating (150#, 300#, 600#, 900#, 1500#, 2500#)

- Size (1/2" - 96")

- Flat or RTJ Male or Female Face (Octagonal or Oval cut)

- Mill or Serrated Finish

- Blind Thickness (Isolation, Hydro, Custom)

- # of Ports

- Port Type (NPT, SW)

- Port Location(s)

- Steel Material Type (Carbon, Stainless - 304, 316, Other)

- Quantity Needed

- Necessary Delivery Date

Protect Your ½"–14" Paddle Blinds with the Patented EZ Lock Blind Rack®

— Safely Store 16" and Larger Paddle Blinds with the Stackable, EZ Store Storage Rack.

Rent or Buy the Patented EZ Lock Blind Rack from the Industry Leader in Blind Storage Solutions!

A Vented Paddle Blind serves multiple critical functions in pipeline systems:

- Pressure Relief: Prevents damage by allowing controlled pressure release when limits are exceeded.

- Pressure Equalization: Ensures safe removal by balancing pressure on both sides.

- Hydrostatic Testing Support: Facilitates controlled filling and draining for accurate testing.

- Fluid Draining: Enables safe removal of trapped fluids during maintenance.

- Gas/Vapor Venting: Releases trapped gases to prevent hazardous pressure buildup.

- Vacuum Prevention: Gradually introduces air to avoid vacuum formation when removing the blind.

We offer product demos upon request. Ask for an EZ Vent product demo, and our specialists will visit your site to demonstrate how to enhance safety without extending job completion time.

Paddle Blinds, Specialty Slip Blinds & Blind Flanges

Frequently Asked Questions

Yes, multiple ports can easily be added, and we can add them on both sides upon request! Please specify how many and whether you want them on the upstream or downstream side of the blinds on your quote request.

Sometimes. For every NPT or Socketweld blind, there is a minimum thickness required, which is also determined by whether or not the blind needs to be rated for pressure. We can easily make your blind thicker to meet custom needs.

No, since the smallest tap size is 1/8" NPT or SW (which would require a .410 hole) it would need to be a minimum of 1/2" thick.

No. Our internal standard is to place the port at approximately 180 degrees from the handle with no interference between the connection and the bolts. However, if you need the connection point in a different location on the blind, we can manufacture it to your specs.

When requesting an alternate port placement, we recommend that you specify where in relation to the handle you would like the port(s) to be located (ie. approximately 90 Degrees from handle) and note that the vent must be located between bolt holes.

Yes! We can completely customize blind thicknesses to your needs.

Our EZ Vent blinds are easily identified by the "V" notch that we place in the top of the handle.

We always identify the vented side of the EZ Vent blind for you by marking it "EZ VENT," "EZVB," or "VENT" on the handle. Regardless, the vented side will always be the side with text markings. If you would like us to mark it in some other fashion for your needs that's EZ!

They are available for either rental or purchase, depending on your needs. Some restrictions apply.

Yes, just let us know your requirements. We can completely customize our products to your needs, and we regularly finish our blinds with a Machined 125-250 rms finish or an RTJ (RJ) for the gasket area.

Absolutely. We manufacture our EZ Vent Blinds and Spectacle blinds in house, and we're happy to put a port in a spectacle blind of any size or rating.