Paddle Blinds / Line Blanks for Piping Systems

Isolation, Hydrotest & Custom Thicknesses | 1/2" - 96" | Same-Day Shipping / Delivery Available

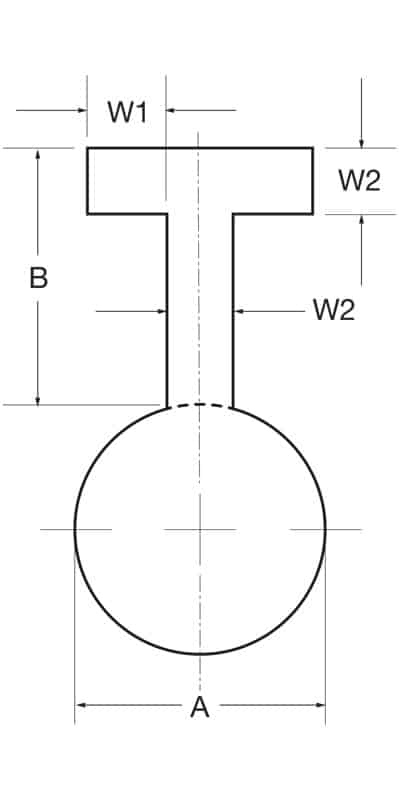

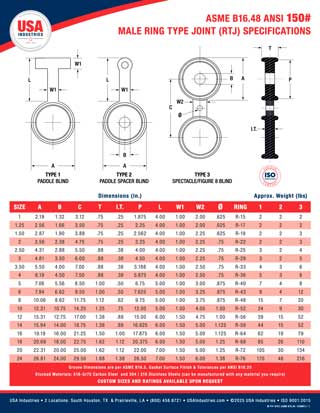

PADDLE BLIND / LINE BLIND SPECS:

| Sizes: | 1/2" - 96" |

| Thickness Options: | Isolation • Hydro • Custom |

| Rating Classes: | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Stocked Alloys: | 516-Gr70 CS • 304/316 SS (Any Available Alloy) |

| Materials Origin: | USA |

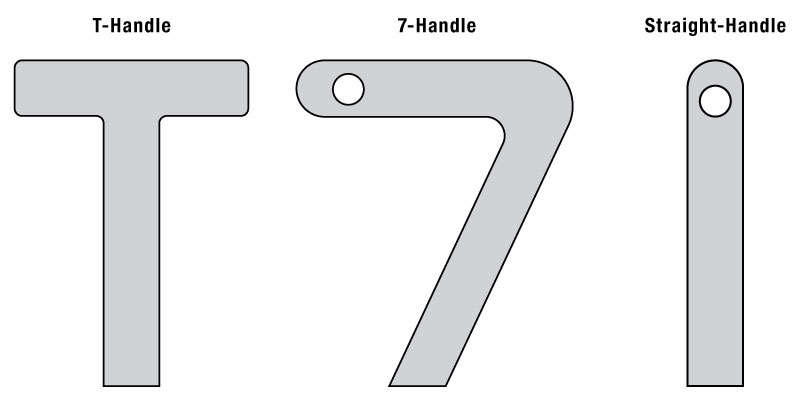

| Handle Options: | T • 7 • Straight

|

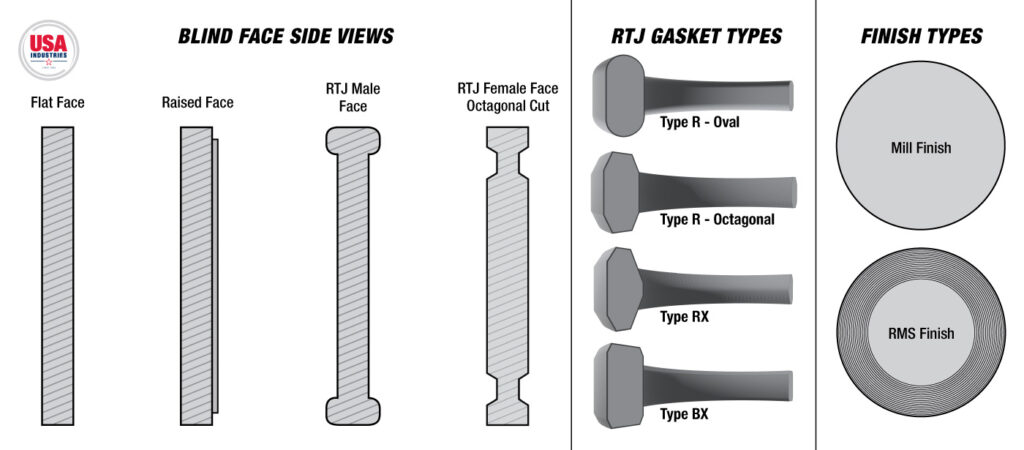

| Face Options: | Flat • Raised • RTJ Male • RTJ Female |

| Gasket Types: | Octagonal • Oval |

| Finish Options: | Serrated (125/250 RMS) • Mill |

| Coating Options: | Various |

| ASME Standards: | B16.48 • B16.47 (26" & Larger - Series A & B) • B16.5 |

| NSF ANSI/CAN 61 Certification: | NSF ANSI/CAN 61 certification applies exclusively to our stainless steel products |

To Order Call: (800) 456-8721 — Specify:

- Flange Rating (150#, 300#, 600#, 900#, 1500#, 2500#)

- Size (1/2" - 96")

- Face Type (Flat, Raised, RTJ - Male or Female (if Female: Oval or Octagonal cut)

- Mill or Serrated Finish

- Blind Thickness (Isolation, Hydro, Custom)

- Handle Type (T, 7, Straight)

- Steel Material Type (Carbon, Stainless - 304, 316, Other)

- Quantity Needed

- Necessary Delivery Date

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Color-Coded Handles

Easy rating identification with color-coded handle system.

100% USA Materials

All raw materials sourced from American mills.

USA Industries Blind Processing

See what makes our blinds different from the competition

Manufactured In-House

Complete control over quality and lead times

U.S. Produced Steel

All raw materials from American mills

PMI All Raw Materials

Positive material identification on every piece

Waterjet & Plasma Cut Materials

Precision cutting for exact specifications

Cut Deburring

Smooth, safe edges on every blind

QC Verified Cuts

Quality control inspection on all products

Stamped with Blind Specs

Clear identification of ratings and specifications

Color-Coded by Class Rating

Instant visual identification system

Painted (Carbon Steel)

Protected against corrosion

Order Verification

Double-checked before shipment

NSF ANSI/CAN 61 Certified

For Stainless Steel Blinds

Why Our Blinds Are Different

We are the actual manufacturer, not just a reseller. Since 1982, using advanced CNC plasma and waterjet machines, each blind is crafted with perfect symmetry, clean edges, fresh paint, marked or stamped, and color-coded handles for easy flange rating identification. Also, our blind solutions are crafted from top-grade alloys, including carbon steel, stainless steel, and other specialized materials known for their strength, durability, and corrosion resistance.

Moreover, unlike others who may claim this, USA Industries has the largest stock for immediate delivery and in-house production.

Additional Information

Need Blind Storage?

Protect Your 1/2"–14" Paddle Blinds with the Patented EZ Lock Blind Rack®

Rent or Buy the Patented EZ Lock Blind Rack from the Industry Leader in Blind Storage Solutions!

- Safely store and organize paddle and spectacle blinds

- Stackable design for 16" and larger blinds

- Rental and purchase options available

- Reduces handling damage and improves organization

ABOUT PADDLE BLINDS / LINE BLANKS:

Paddle Blinds, are inserted between two flanges within piping systems.

- Function: First and foremost, paddle blinds temporarily stop or regulate flow during inspections, repairs, or testing.

- Material: Additionally, manufacturers use carbon steel, stainless steel, or other durable alloys to ensure paddle blinds withstand high pressures and temperatures.

- Advantages: Moreover, these blinds are easy to install and remove, cost-effective, and reliable for system isolation.

- Applications: As a result, industries such as refineries, chemical plants, petrochemical plants, cement plants, steel mills, storage terminals, and food processing facilities commonly use them.

- Alternative Names: Finally, paddle blinds may also be referred to as paddle blank, line blank, skillet blind, pancake blind, spade blind, isolation blind, or test blind.

Paddle Blind 3D Product Rotation

USA Industries NSF ANSI/CAN 61 certification applies exclusively to our stainless steel products.

NSF/ANSI 61 is the NSF standard ensures that any materials, coatings, or products that come into contact with drinking water do not leach harmful contaminants into the water at unsafe levels.

NSF 61 Covers:

- Pipes & fittings (metal, plastic, concrete, etc.)

- Valves & gaskets

- Meters & water treatment devices

- Coatings, linings, sealants, solders

- Any materials that touch drinking water in distribution systems

It Tests For:

- Leaching of lead, arsenic, mercury, and other heavy metals

- Leaching of organic contaminants (e.g., solvents, plasticizers)

- Other harmful chemicals that might migrate from the material into water

Why It Matters:

- It’s a regulatory requirement in most U.S. states and Canadian provinces for products used in public water systems.

- Products with NSF/ANSI 61 certification give assurance that they are safe for use with potable (drinking) water.

We are committed to continuous innovation in piping isolation solutions, consistently enhancing our products to meet your needs. Our custom slip blind offerings include the exclusive EZ Vent-Purge®, EZ Vent®, EZ Purge®, and EZ Guillotine™ slip blinds, designed for optimal performance and efficiency. Additionally, we manufacture the patented EZ Lock Blind Rack®, a premier inventory management system that ensures secure storage, easy transportation, and enhanced organization, preventing common issues related to handling and safeguarding your blinds.

Paddle Blinds, Specialty Slip Blinds & Blind Flanges

Frequently Asked Questions

Our steel plates are proudly sourced and manufactured in the United States. We work with trusted vendors who purchase their alloys from American mills that meet stringent quality and environmental standards, ensuring top performance and consistency in every product.

Absolutely. We can provide mill test reports (MTRs) and country of origin documentation upon request for your records or compliance needs.

We are the actual manufacturer, not just a reseller. Since 1982, each blind is crafted with perfect symmetry, clean edges, fresh paint, marked or stamped, and color-coded handles for easy flange rating identification. Moreover, unlike others who may claim this, USA Industries has the largest stock for immediate delivery and in-house production.

Most requests are for 5/16" thickness, although 1/4" or 3/8" are also very common.

T-handles, 7 handles, and Straight handle. We can also make custom handles for you.

Yes. We will customize your blind to your exact specifications.

We stock our isolation and hydrotest blinds with a mill finish and offer a 125/250 RMS serrated finish as a standard option, but we can manufacture to your exact requirements.

The term "paddle blind" is a general term that doesn't specify the thickness or purpose of the blind (whether for isolation or testing).

A "hydroblind," also known as a "hydrotest blind," is designed to withstand the maximum pressure during pipe testing according to ASME specifications.

Some companies exclusively use hydroblinds for isolation or testing, considering it a safer option. This ensures the blind can withstand latent pressure buildup in the line, unlike the 5/16" thickness isolation blind that might fail if the pressure rises significantly.

This is dependent on the flange's ASME rating. Sizes and thickness are manufactured to the ASME 16.48, API 590, ASME 16.5 specifications and will hold the pressure that the spec calls for.

We will manufacture your paddle blind(s) in any alloy you require, so long as the material is available.

Our color-coded handles allow you to easily identify the flange rating for the blind(s) you need.

150#: Red

300#: Blue

600#: Yellow

900#: Green

1500#: White

2500#: Orange

Yes. A Paddle Blinds is also referred to as a paddle flange, paddle blank, blind spade, line spade, isolation or test blind, flange skillet, pancake skillet, pancake blind, slip blind, blank blind, and more.