Sacrificial

Zinc Anodes

Equipment

Damage

| Size NPT (in.) | Rod Diameter (in.) | Rod Length (in.) | Part No. |

|---|---|---|---|

| 1/4 | 1/4 | 1 | AP-0250-1 |

| 1/4 | 1/4 | 2 | AP-0250-2 |

| 1/4 | 1/4 | 3 | AP-0250-3 |

| 1/4 | 1/4 | 6 | AP-0250-6 |

| 3/8 | 3/8 | 2 | AP-0375-2 |

| 3/8 | 3/8 | 3 | AP-0375-3 |

| 3/8 | 3/8 | 6 | AP-0375-6 |

| 1/2 | 1/2 | 3 | AP-0500-3 |

| 1/2 | 1/2 | 6 | AP-0500-6 |

| 1/2 | 1/2 | 8 | AP-0500-8 |

| 3/4 | 3/4 | 4 | AP-0750-4 |

| 3/4 | 3/4 | 6 | AP-0750-6 |

| 3/4 | 3/4 | 8 | AP-0750-8 |

| 1 | 1 | 4 | AP-1000-4 |

| 1 | 1 | 6 | AP-1000-6 |

| 1 | 1 | 1 | AP-1000-10 |

| 1 | 1 | 14 | AP-1000-14 |

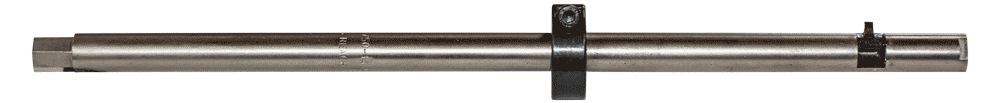

ZINC ANODE/ BOAT ZINC PRODUCT FEATURES:

- Prevent damage from galvanic corrosion

- Rod lengths available from 1" to 14"

- Rod diameters available from 1/4" to 1"*

- Replaceable zinc anode

- Soft rubber material conforms to provide a tight seal

- In-stock items ship within 24 hours

For sizes larger than 1" NPT, use 1" parts and install a reducing bushing

For use in heat exchangers, pumps, tanks, pipelines and engines

Other Names/Uses

- Boat Pencil Zincs, Pencil Anodes, Engine Anodes, Marine Zincs, Zinc Engine Anodes, Pencil Zinc Engine Anodes, Galvanic Corrosion Anodes, Galvanic Sacrificial Anodes

HOW ZINC ANODES WORK:

Heat exchangers, often made of copper alloy, are prone to galvanic corrosion. Zinc Anode Header Plugs are commonly installed in them to prevent this. These plugs can be found in the exchanger and are easily replaceable. It's advisable to check internal anodes annually if your equipment has them.

Sacrificial anodes work by preventing galvanic corrosion. When two different metals are connected and exposed to seawater, they generate electrical current, leading to corrosion. To counter this, a third metal, faster to corrode than the other two, is introduced to the circuit, sacrificing itself to protect the other metals.

Replacement anodes are available separately, eliminating the need to buy the entire plug assembly.

Technical Documents

Frequently Asked Questions

We are a full machine shop, and we're capable of customizing your anode plug to your exact spec. Please contact us with your project details, and we'll be happy to assist you.

The NPT on our anodes are made of brass.

Seawater, and other kinds of water, can create an electrical current between two metals that results in corrosion. By introducing a third metal that 'sacrifices' itself before the other metals start to corrode, you have an easily replaceable part that prevents corrosion on your equipment.

We suggest you check your anodes every 6-12 months.

Absolutely. We're happy to sell you just the anode, please contact us with the size of rod you need, and the dimensions on your existing plug.

Heat exchangers, pumps, tanks, pipelines and engines are all common equipment that have anode plugs built in. Boats and other equipment that are regularly subjected to seawater have a higher chance of corrosion and may benefit from a zinc anode plug.

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Engineering Innovation

Precision-Engineered Industrial Solutions — Delivered Fast!

100% USA Materials

All raw materials sourced from American mills.