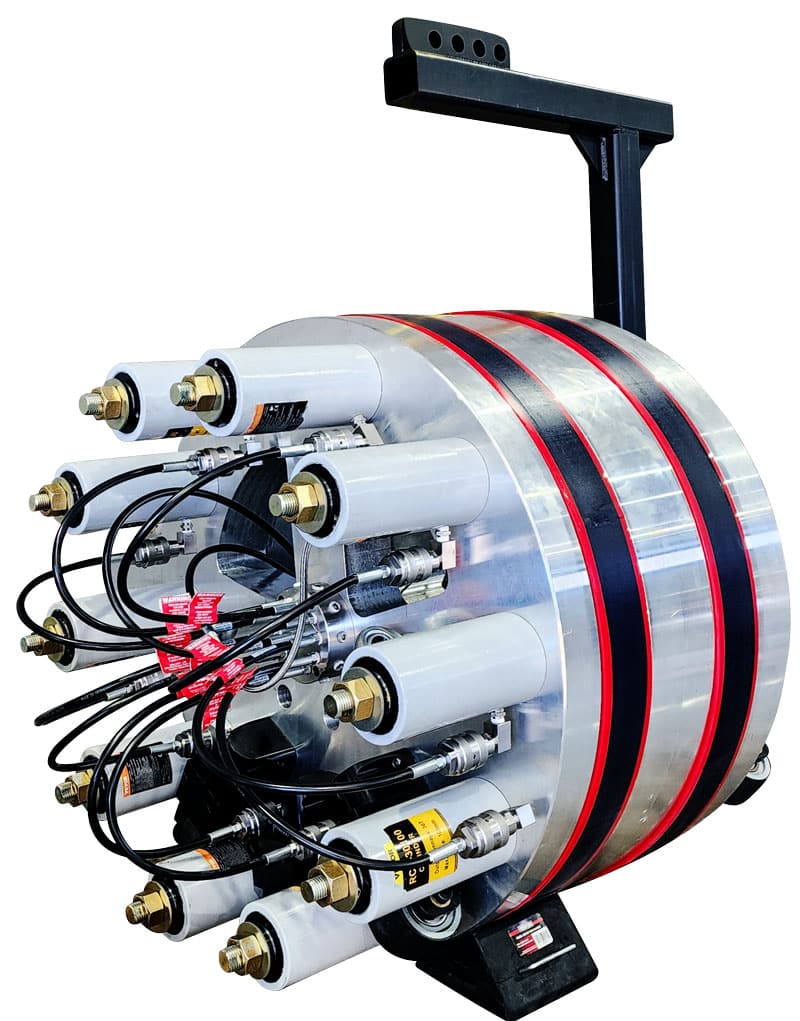

Custom Engineered Rolling DBB Plug

Technologies that will result in dramatic time, manpower and cost savings!

Custom Rolling DBB Plug — Specs

| Sizes | Custom-engineered for your exact pipe diameter |

| Isolation Type | Double Block & Bleed (DBB) — non-gripping |

| Seal Technology | Ultra-Wide Tri-Ply® Seals (Patented multi-durometer) |

| Seal Actuation | EZ Turn Hydraulic Actuator Cylinders™ — fully synchronous, no manual intervention |

| Mobility System | EZ Slide Heavy Duty Mounted Casters™ |

| Positioning Aid | EZ Align Fit-Up Clamp™ — short and long distances |

| Weld Locating | Internally Mounted Digital Camera with LED Lighting |

| Application | LNG, Petrochemical, Industrial Pipelines |

| Pressure Rating | Engineered to project specification |

| Origin | USA — 100% manufactured in-house |

Engineered Accessories —

Technologies That Save You Time & Money

Every accessory is purpose-engineered to eliminate labor, reduce risk, and speed up your project timeline.

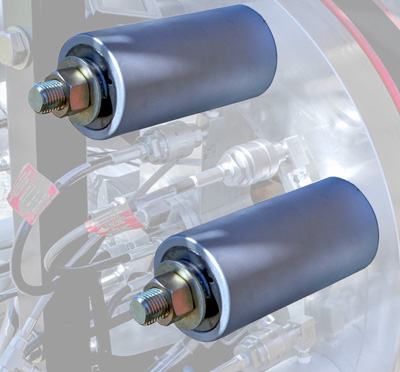

EZ Turn Hydraulic Actuator Cylinders™ Patented

Synchronous hydraulic tightening and loosening of seal expansion nuts, which in turn expands and contracts the plug seals. No manual intervention is required, equaling a dramatic time and labor cost savings to you and your project budget.

Traditional pipe plugs require workers to manually torque multiple expansion nuts — a time-consuming and physically demanding process, especially in large-diameter piping. The EZ Turn system actuates all seals simultaneously with a single hydraulic operation, reducing seal deployment time by a significant margin.

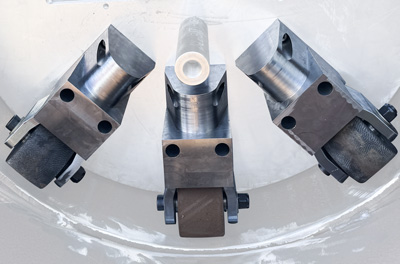

EZ Slide Heavy Duty Mounted Casters™ Exclusive

Casters provide fluid movement of oversized and heavy-weighted isolation plugs inside the pipe. Consequently, the casters require very little physical exertion to position or reposition the pipe plug once seated in the pipe.

For large-diameter piping, plug weight can run into hundreds of pounds. The EZ Slide caster system distributes that load and allows a single operator to smoothly maneuver the plug into position without heavy lifting equipment.

EZ Align Fit-Up Clamp™ Exclusive

Clamp latches onto third-party device in order to slide the oversized and heavy-weighted isolation plug into place over short and long distances.

Whether you're inserting the plug from a crane, forklift, or tugger, the EZ Align Clamp creates a secure mechanical connection that keeps the plug properly oriented during travel — critical for accurate seating in large-diameter pipe runs.

Internally Mounted Digital Camera with LED Lighting Smart Tech

Internally mounted camera allows you to perfectly locate the weld seam. There is no more guessing, or requiring you to measure short and long distances in order to seat the plug properly in place before beginning your project operation.

The live camera feed is displayed externally so the operator can see exactly where the seals will land relative to the weld zone — eliminating one of the most common causes of failed isolation tests.

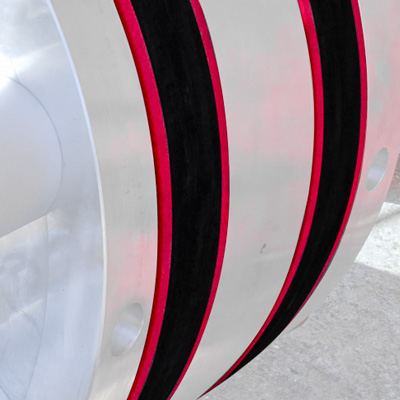

Ultra-Wide Tri-Ply® Seals Patented

The patented multi-durometer Tri-Ply Seal provides a larger surface coverage area over the standard seal, resulting in a greater expansion range, and eliminates seal mushrooming that happens from over-torquing the seal expansion nuts.

Standard seals rely on a single durometer compound and a narrow contact band. The Tri-Ply design bonds three layers of different hardness ratings into a single seal body, creating a wide, self-distributing contact zone that adapts to minor ID variations — common in fabricated and welded large-diameter pipe.

Additional Information

Rolling DBB Plug — Full Operation Demonstration

Watch a live demonstration of the complete DBB plug system, including hydraulic seal actuation, caster-assisted insertion, and camera-guided weld-seam positioning.

- Hydraulic actuator synchronous seal expansion

- EZ Slide caster insertion into large-diameter pipe

- Internal camera weld-seam location procedure

- EZ Align clamp engagement and release

- Full DBB pressure test cycle