VLD-2500 Vacuum Leak Detector

Reliably pinpoint tube leaks in heat exchanger tubes within seconds!

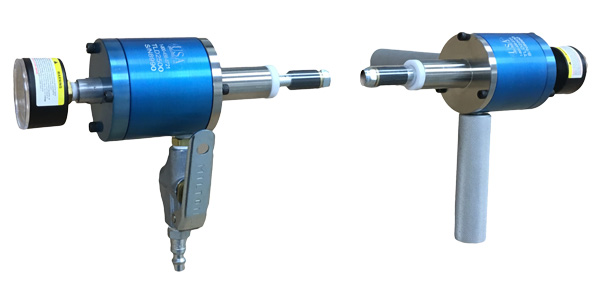

The VLD-2500 Vacuum Leak Detector plays a crucial role in ensuring the integrity and efficiency of heat exchanger tubes. Heat exchanger tubes are essential components in systems used for heating, cooling, and energy transfer processes across industries such as power generation, chemical processing, HVAC, and petroleum refining. Simply seal one end of the tube with a rubber plug or a t-handle with a nozzle, then insert the detector into the tube to be tested and press the trigger. If there's a leak, the VLD-2500 reliably detects it with high precision. It tool includes a filter system to stop debris from blocking its detection mechanism.

VLD-2500 PRODUCT FEATURES & BENEFITS

Using a vacuum leak detector to identify leaks in heat exchanger tubes offers numerous benefits that enhance operational efficiency, safety, and maintenance effectiveness. Heat exchangers play a critical role in various industrial processes, and even small leaks can lead to significant performance losses, contamination, and safety hazards. Vacuum leak detection provides a highly sensitive, accurate, and non-destructive method to pinpoint leaks early before they escalate into costly failures.

From a maintenance perspective, regular use of vacuum leak detectors as part of a preventive maintenance program helps extend the service life of heat exchangers, improves reliability, and reduces unexpected outages. In industries such as power generation, petrochemicals, and HVAC, where heat exchanger performance is critical, vacuum leak detection ensures regulatory compliance, energy efficiency, and operational safety.

- Easy-to-use

- Detects leaks in tubes sized 1/4" to 3" OD almost instantly

- Operates with standard plant air pressure of 70 psi to 100 psi

- Includes flexible nozzles for effortless tube sealing

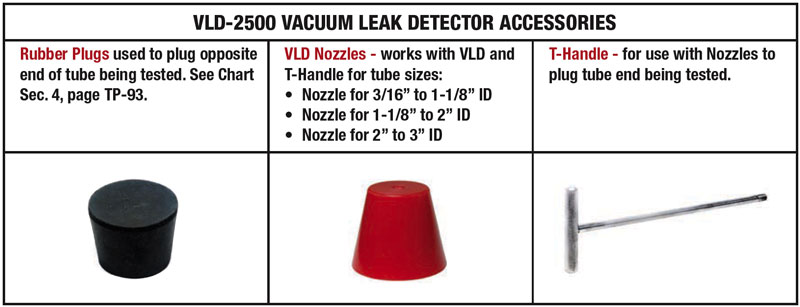

Spare nozzles work with Gun and T Handle

Complete VLD-2500 kit is provided with the following:

• VLD-2500 Vacuum Leak Detector w/Carrying Case

• 12" Extension Tube & T-Handle

• Nozzle - for 3/16" - 11/8" ID Tubes (other sizes Available)

• Rubber Tube Plugs (Qty 4) - to fit 5/8" 13-24 ga Tubes

• Rubber Tube Plugs (Qty 4) - to fit 3/4" 14-24 ga Tubes

• Rubber Tube Plugs (Qty 4) - to fit 1" 11-24 ga Tubes