Isolate & test sections of pipe without the need for flanges! The standard plugs can be used for test pressures up to 3,000 PSIG, in line sizes from 1/2" to 24", and schedules 40 or 80 pipe. This test plug is held in place as the steel threads grip tight with neoprene seals - all by tightening one compression nut!

Grip Type High Pressure Pipe Plug Benefits:

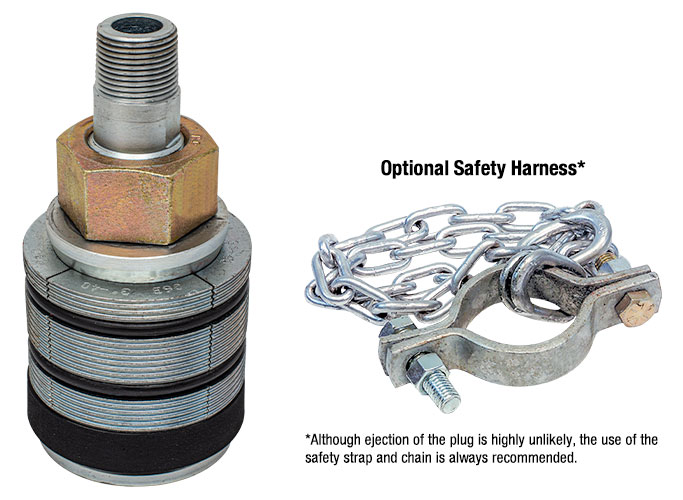

High-pressure pipe testing is safer than ever before, thanks to USA Industries' Grip Type High-Pressure Pipe Plug. Unlike other plugs that can loosen and eject under high pressure - even becoming dangerous projectiles - the Grip Type Test Plug actually uses test pressure to seal more securely against the pipe's inner diameter. The greater the pressure - the tighter the grip! The result is safer installation, better sealing and all around safer testing.

Fast, Easy, Safe Testing:

- Eliminates costly, time consuming practice of welding end caps. Plugs install quickly and are reusable.

High Pressure Performance:

- These plugs grip tightly, meaning operating pressures are limited by the strength of your pipe, not the test plug.

Engineered Seal Design:

- Reduces seal wear for long-lasting performance.

Superior Plug Design:

- Positional washer prevents plug loss & eliminates plug lock-up after hydrotest, common with inferior designs.

Simple Maintenance:

- Replacement seals and grippers are readily available and easy to replace.

Quality Assurance Standard:

- Manufactured under a Quality Assurance Program certified to ISO 9001

Industry-Leading Turnaround Time:

- 1/2" to 24" in Sch 40 and 80 (DN15 to DN600) sizes are typically in-stock and ship same day.

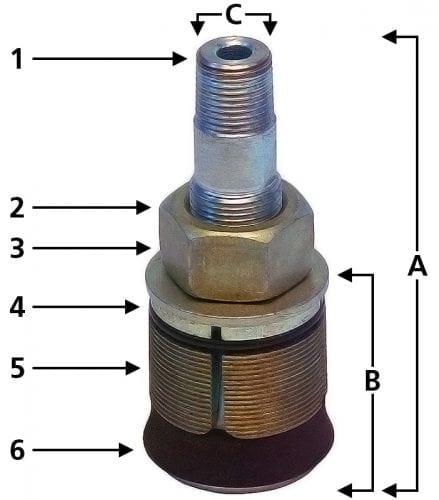

| Ref # | Part | Material |

|---|---|---|

| 1 | Mandrel | Steel |

| 2 | Hex Nut | Steel |

| 3 | Washer | Steel |

| 4 | O-Ring | Buna N |

| 5 | Grips | Steel |

| 6 | Seal Cups | Neoprene |

Dimensions of GripType High Pressure Plugs

| Plug Type |

Size (Sch 40 & 80) |

A Dim |

B Dim |

C Dim |

Plug Weight |

Stem Hole Size |

Nut Size |

|---|---|---|---|---|---|---|---|

| "C" | .466 to .680" | 3 3/4" | 1 1/4" | 1/8"* | 5 oz. | 3/16" | 5/8" - 18 |

| .700 to 1" | 3 3/4" | 1 1/4" | 1/4" | 5 oz. | 1/4" | 5/8" - 18 | |

| "D" | 1" | 4" | 1 1/2" | 1/4" | 8 oz. | 1/4" | 5/8" - 18 |

| 1 1/4" | 4" | 1 1/2" | 1/4" | 12 oz. | 1/4" | 5/8" - 18 | |

| 1 1/2" | 4 1/2" | 1 3/4" | 3/8" | 1 lb. | 3/8" | 7/8" - 14 | |

| 2" | 5" | 2" | 1/2" | 2 lb. | 3/8" | 1" - 14 | |

| 2 1/2" | 5 1/4" | 2" | 3/4" | 4 lb. | 3/8" | 1 1/4" - 12 | |

| 3" | 5 3/4" | 3" | 3/4" | 6 lb. | 5/8" | 1 1/4" - 12 | |

| 4" | 5 3/4" | 3" | 3/4" | 10 lb. | 5/8" | 1 1/4" - 12 | |

| 5" | 6" | 3 1/4" | 3/4" | 14 lb. | 3/5" | 1 1/4" - 12 | |

| 6" | 6 1/2" | 3 1/2" | 1" | 21 lb. | 8/9" | 1 1/2" - 12 | |

| 8" | 7" | 3 3/4" | 1" | 40 lb. | 8/9" | 1 1/2" - 12 | |

| 10" | 7 1/2" | 3 3/4" | 1" | 70 lb. | 1" | 1 1/2" - 12 | |

| 12" | 8" | 4" | 1 1/4" | 100 lb. | 1" | 2" - 12 | |

| 13" | 8" | 4" | 1 1/4" | 132 lb. | 1" | ||

| 14" | 8" | 4" | 1 1/4" | 132 lb. | 1" | ||

| 15" | 8 1/2" | 4 23/32" | 1 1/4" | 171 lb. | 1" | ||

| 16" | 8 1/2" | 4 23/32" | 1 1/4" | 171 lb. | 1" | ||

| 17" | 8 1/2" | 4 1/2" | 1 1/4" | 210 lb. | 1" | ||

| 18" | 8 1/2" | 4 1/2" | 1 1/4" | 210 lb. | 1" | ||

| 19" | 9" | 5" | 1 1/4" | 270 lb. | 1" | ||

| 20" | 9" | 5" | 1 1/4" | 270 lb. | 1" |

A Critical Reminder: Conducting pressure testing poses significant hazards, demanding strict adherence to safety protocols. Ensure all connections, valves, flanges, and fittings are suitable for pressure testing. Verify the compatibility of line ID & Plug Range. Most importantly, never position yourself in front of a test plug or enclosure during testing. Discharge from a plug during testing could result in severe injury or fatality.

Frequently Asked Questions

Yes, just let us know at the time of order, and we can customize this plug to your needs.

Yes, up to 3,000 PSIG is standard, however, once above 12" the rated pressure begins to drop due to the area, and at 24" the current design is rated to 750 PSIG.

Yes, these can be provided for any schedule pipe. Stocked schedules are typically schedules 40S and 80S.

Yes, the use of the safety strap and chain is always recommended.

It will cause some scarring to the ID of your pipe, especially with higher pressures. This is the trade off for technician and plant safety.

No, just a properly sized wrench, socket, crescent, or pipe wrench to tighten up one compression nut. (Note: the 20" and 24" plugs have multiple nuts.)

Yes, we're happy to provide replacement kits as needed.

For all sizes 2" and above you need about 200 ft/lbs to ensure proper installation. As the plug sees pressure, the design causes the plug to seat itself harder into the pipe.