Metal Tapered

Hammer-in Plugs

WEEKS

TO DAYS!

Metal Tapered Plug Benefits:

| Stocked Part Numbers: |

TP-1 through TP-28; custom plugs available to any required size |

| Stocked Materials: |

A-105 Carbon Steel, 304/316 Stainless Steel, Brass; custom plugs can be rapidly manufactured in any required alloy |

| Material Origin: |

All alloy materials milled in the USA |

| Production Capacity: |

Over 5,000 plugs per day |

Availability & Delivery:

- In-stock items ship within 24 hours

- Same-day local delivery available in Texas and Louisiana

Installation Guidance:

- Use correct plug size based on tube O.D. and gauge for optimal sealing without tubesheet damage

- Tube plug and tube metal should always match for best results

- Custom Solutions: Engineering support available for special sizes or alloys

- Quality Assurance: All plugs manufactured to meet rigorous testing and performance standards

To Order Call: (800) 456-8721 — Specify:

- TP No. Based on Size of Your Plug (see chart)

- Material Type (ie., Carbon Steel, Stainless - 316, Brass, Inconel, etc.)

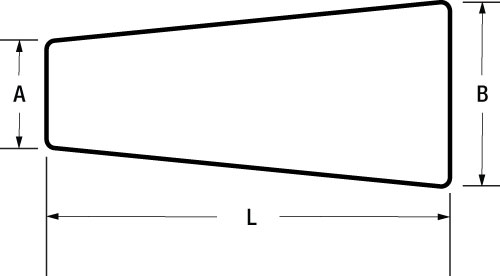

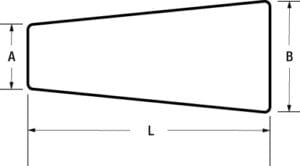

- For Custom Plugs, Provide A, B & L Dimensions

- Quantity Needed

- Necessary Delivery Date

METAL TAPERED TUBE PLUG BENEFITS

Low-Cost & Quick Sealing Solution:

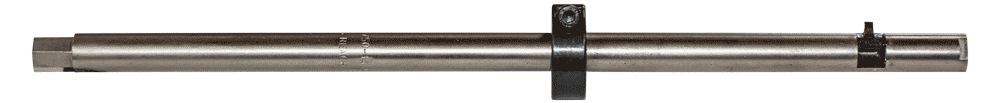

- Easily installed one-piece tapered tube plugs.

- Establishes a positive seal with minimal driving force in seconds.

- Quickly restores Fin-Fan® / air-cooled heat exchangers, boilers, or condensers.

Material Compatibility & Customization:

- Tube plug and tube metal should match for optimal performance.

- Stocked in over 20 metals.

- Custom plugs available in any material and coating upon request.

Industry Leader in Tube Plug Solutions:

- Serving oil & gas, chemical, and power industries.

- Over 500,000 tube plugs in stock, ready to ship.

- Production capacity exceeds 5,000 plugs per day.

TP-1, TP-2, TP-3, TP-4, TP-5, TP-6, TP-7, TP-8, TP-9, TP-10, TP-11, TP-12, TP-13, TP-14, TP-15, TP-16, TP-17, TP-18, TP-19, TP-20, TP-21, TP-22, TP-23, TP-24, TP-25, TP-26, TP-27, TP-28, TP-MT

TP1, TP2, TP3, TP4, TP5, TP6, TP7, TP8, TP9, TP10, TP11, TP12, TP13, TP14, TP15, TP16, TP17, TP18, TP19, TP20, TP21, TP22, TP23, TP24, TP25, TP26, TP27, TP28, TPMT

Technical Documents

Frequently Asked Questions

The X is a placeholder for material type (e.g. Carbon, Stainless, Monel, etc..). Simply replace that with what ever material you need!

We manufacture all of our plugs in house, and are not limited by size. We can produce more than 5,000 plugs per day, at any size!

Tapered tube plugs are generally installed with a hammer. We strongly suggest using a tube cutter to puncture the inside of your tube before installing to prevent pressure building up over time and creating dangerous projectiles.

We will always recommend you puncture the tube before installing a tube plug to prevent pressure from building up and creating a dangerous tube plug projectile.

Yes. This is a common technique for ensuring a stronger seal.

We can recommend size(s) based on your inside diameter. Call us today and we'll be happy to help!

We are proud to be able to offer our products in more than 20 different materials. We've probably worked with whatever material you need in the past, and we're happy to make custom plugs on request, 24/7, 365 days a year!

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Engineering Innovation

Precision-Engineered Industrial Solutions — Delivered Fast!

100% USA Materials

All raw materials sourced from American mills.