EZ Vent-Purge®

Combo Paddle Blind

Money.

Rent.

The EZ Vent-Purge slip blind combines the benefits of EZ Vent® and EZ Purge® into one tool! Purge the line safely during "Hot Work" using the Purge side, and then bleed and control pressure or fluids using the Vent side. This combo saves time and money by integrating these two useful blinds into a single tool.

To Order Call:

(800) 456-8721

Specify:

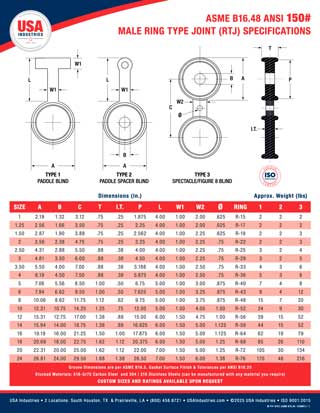

- Flange Rating (150#, 300#, 600#, 900#, 1500#, 2500#)

- Line Size (1/2" - 96")

- Face Type (Mill, Serrated)

- Blind Thickness (Isolation, Hydro, Custom)

- # of Ports

- Port Type (NPT, SW)

- Port Location(s)

- Steel Material Type (Carbon, Stainless - 304, 316, Other)

- Quantity Needed

- Necessary Delivery Date

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Color-Coded Handles

Easy rating identification with color-coded handle system.

100% USA Materials

All raw materials sourced from American mills.

Blind

Processing

What separates USA Industries blinds from the competition — built into every piece.

Why Our Blinds Are Different

We are the actual manufacturer, not just a reseller. Since 1982, using advanced CNC plasma and waterjet machines, each blind is crafted with engineered symmetry, clean edges, fresh paint (carbon steel), marked or stamped, and color-coded handles for easy flange rating identification. Also, our blind solutions are crafted from top-grade, American milled alloys, including carbon steel, stainless steel, and other specialized materials known for their strength, durability, and corrosion resistance.

Moreover, unlike others who may claim this, USA Industries has the largest stock for immediate delivery and in-house production.

Need Blind Storage?

Protect Your 1/2"–14" Paddle Blinds with the Patented EZ Lock Blind Rack®

Rent or Buy the Patented EZ Lock Blind Rack from the Industry Leader in Blind Storage Solutions!

- Safely store and organize paddle and spectacle blinds

- Stackable design for 16" and larger blinds

- Rental and purchase options available

- Reduces handling damage and improves organization

EZ VENT-PURGE PRODUCT USES

- Multiple Ports can be added, venting one or both sides

- Safer, quicker and easier than traditional practices

FOR EZ VENT SIDE:

- Blocks flow on one side while allowing access to relieve or purge the other side.

- Enhances downstream safety in case of a leaking valve upstream.

- Easily verifies zero energy in the line and vents off leaked pressure for hydrotesting.

FOR EZ PURGE SIDE:

- Creates a "standoff" area at the flange site for line purging.

- Seals evenly, avoiding damage to the flange and gasket surfaces compared to outdated practices involving using makeshift spacers.

Technical Documentation

Frequently Asked Questions

Our EZ Vent-Purge blinds are stamped with the line size, flange rating, and the word "VENT" on the vented side, and "PURGE" on the purge side.

We have a special handle designating it is a vent-purge blind, it is a combination of a "V" notch in the middle and one edge of the top will be rounded with a hole in it forming the letter "P" when viewed from the "Purge" side.

Yes! Let us know if you want an NPT or SW connection. Note: This may necessitate an increase of the blind thickness so your request can be accommodated.

Absolutely. As long as there is enough room to accommodate the vent sizes and the purge slots!

Our default thickness is a standard hydrotest thickness plus 1/4" for the purge channels. On smaller lines, because of the NPT, the thickness will be a minimum of 1/2".

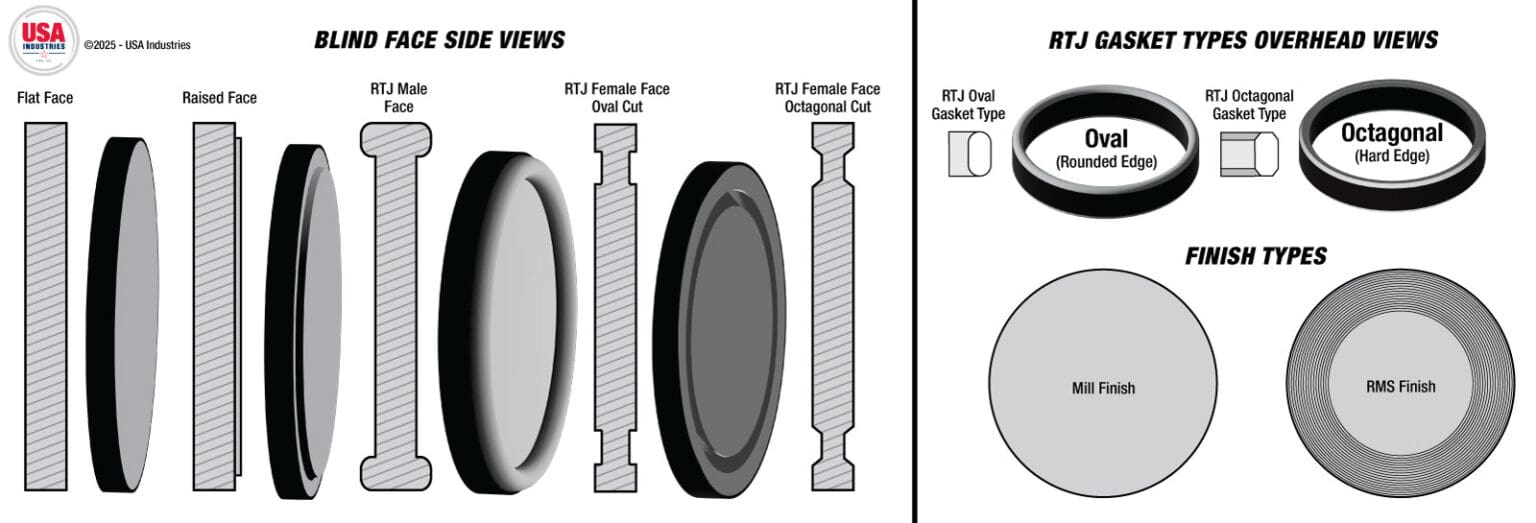

Yes. We can do both machined 125-250 rms finishes and RTJ male or female surfaces upon request.

Typically 1-2 days lead time, but it will depend on how many you need along with any special requirements you might have.

They are available for either rental or purchase, depending on your needs. Some restrictions apply.