Blind Flanges

for Piping Systems

Money.

Rent.

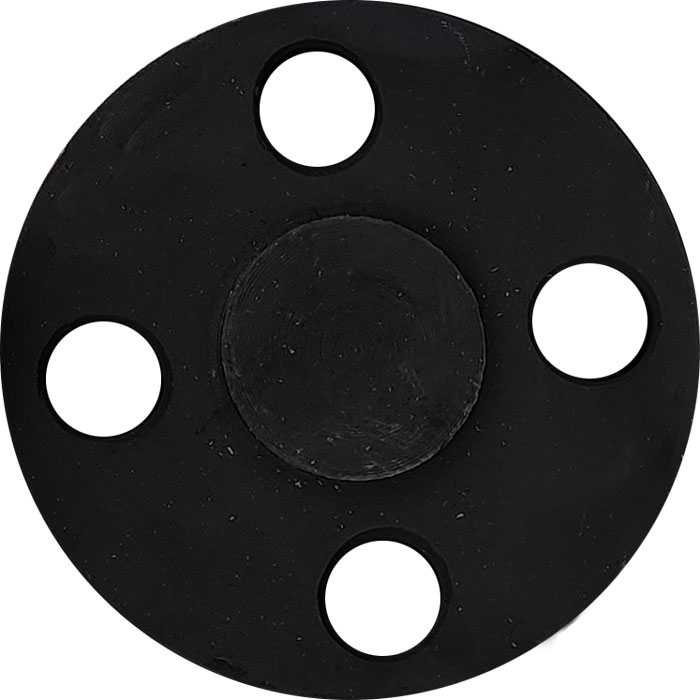

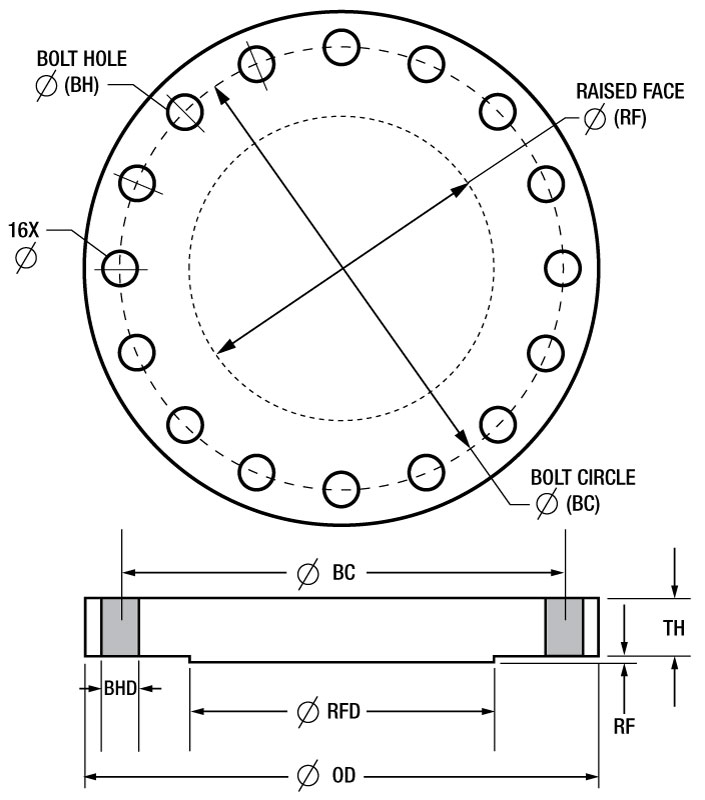

ASME Blind Flange

Specs:

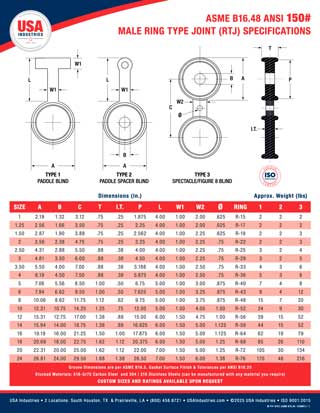

| Sizes: | 1/2" - 96" |

| ASME Pressure Ratings: | 150# • 300# • 600# • 300# • 1500# • 2500 |

| Stocked Alloys: | 516-Gr70 CS • 304/316 SS (Any Available Alloy) |

| Port Options: | NPT or SW |

| Multiple Ports Can Be Added | |

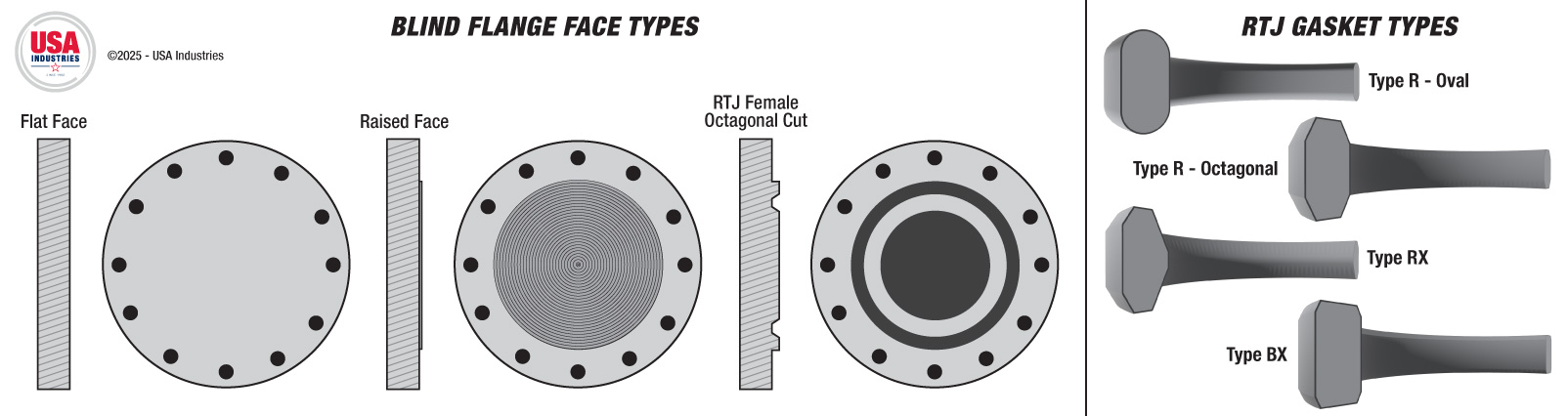

| Face Options: | Raised • Flat • RTJ Male • RTJ Female |

| Coating Options: | Galvanized • Zinc Plated • Yellow Zinc Chromate |

| ASME Standards: | B16.5 • B16.47 Series A & B (26" & Larger) |

- Custom high-pressure flanges made to your specs

- Same-day local shipping/delivery available in Texas and Lousiana

- Your go-to Texas Flange manufacturer for critical applications and custom needs

To Order Call:

(800) 456-8721

Specify:

- Flange Rating (150#, 300#, 600#, 900#, 1500#, 2500#)

- Size (1/2" - 96")

- Vent, Port and Sizes (if required)

- Steel Material Type (Carbon, Stainless - 304, 316, Other)

- Quantity Needed

- Necessary Delivery Date

Additional Information

Need Blind Storage?

Protect Your ½"–12" Blind Flanges with the EZ Lock Blind Flange Rack™ — Safely Store 14" and Larger Blind Flanges with the Stackable, EZ Store Blind Flange Rack Solution.

Rent or Buy the Patented EZ Lock Blind Rack from the Industry Leader in Blind Storage Solutions!

- Safely store and organize blinds flanges

- Stackable design for 16" and larger blinds

- Rental and purchase options available

- Reduces handling damage and improves organization

PIPE BLIND FLANGE USES

- Isolation for Maintenance: Seals pipeline sections for repairs without system shutdown, which improves operational efficiency and reduces downtime.

- Pressure Testing: Acts as a temporary closure for hydrostatic or pneumatic tests.

- Permanent Sealing: Used for decommissioning or abandoning pipeline sections.

- Versatile Applications: Common in oil and gas, chemical processing, power generation, and water treatment industries.

SPECIFICATIONS: Our ANSI flanges are typically manufactured with raised face or Ring Type Joint (RTJ) facing. The standard height is 1/16" for pipe caps under ASME rating 400# and 1/4" for flanges 400# and up. Engineered Flanges. Texas Made. Job-Ready.

NEED PORTS? Choose from middle, top, or bottom ports, and socket weld or NPT vent connections.

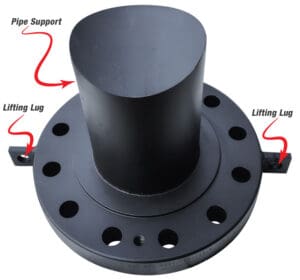

Blind Flange 3D Product Rotation

Technical Documentation

Frequently Asked Questions

No. Blind flanges are used to "close off" the line when bolted to a flange, which is welded to a pipe, heat exchanger, vessel, etc...

Yes. We will custom manufacture or modify any of our products to meet your needs.

Yes. We can produce our products to any custom specification.

This only applies for line sizes greater than 24". Call us and we'll be happy to help you determine the correct spec.

Yes, just let us know if you want the lifting lug on the flat face of the blind flange (typically used when the flange is in a horizontal plane) or on the outer edge (typically used when installing in a vertical plane).

The most common material is A105 grade carbon steel, however we can produce our blinds in any material, grade or alloy you require.

Yes, we can supply the nuts, bolts, and gaskets if you need them.

Yes, we can provide your flange with one or more vents. Vents are available in the middle, top, or bottom of your flange and with socketweld or NPT vent connections.