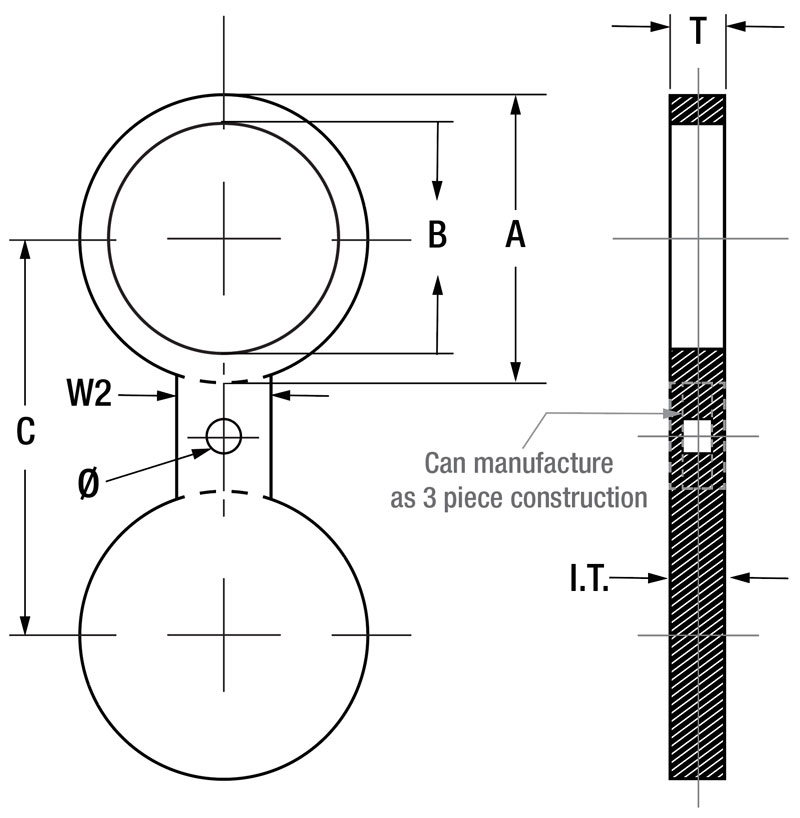

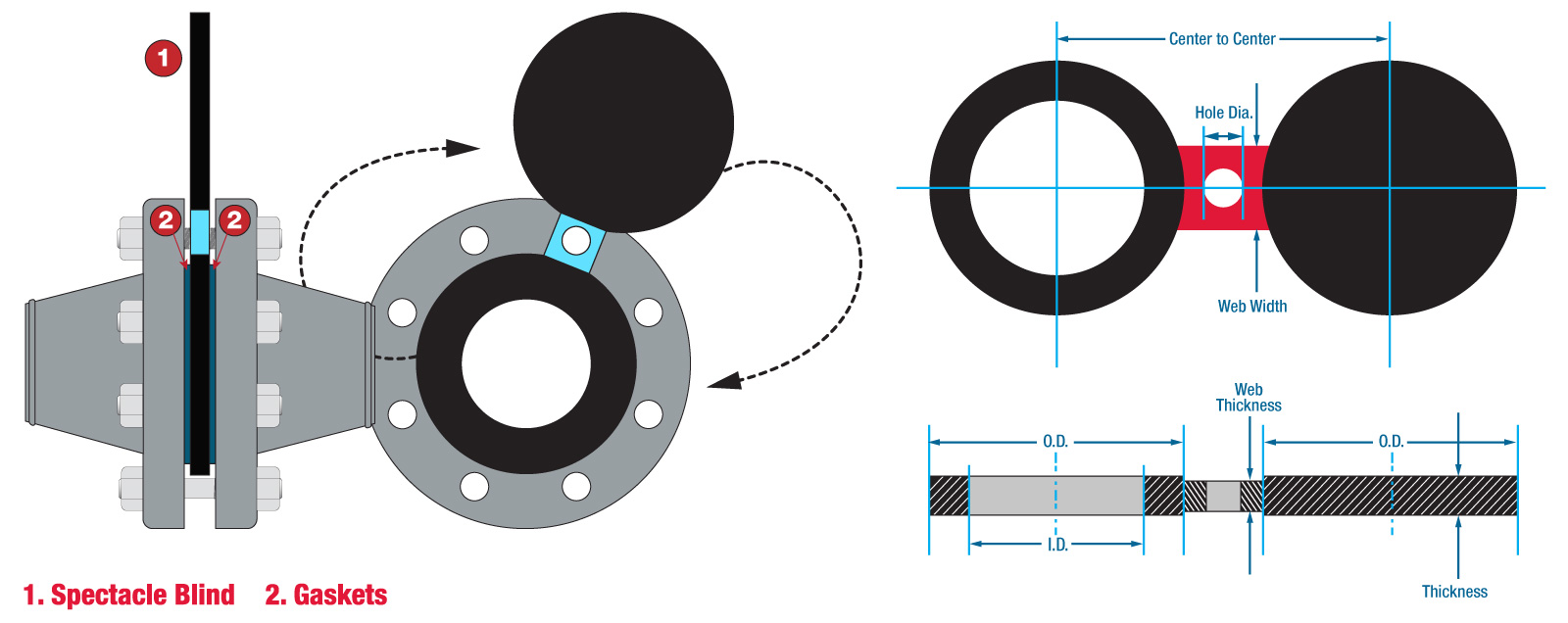

Spectacle Blinds (Figure 8)

for Piping Systems

Money.

Rent.

Spectacle Blind

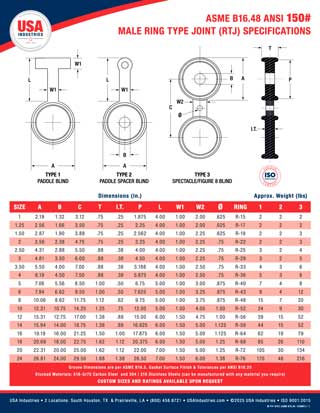

(Figure 8) Specs:

| Sizes: | 1/2" - 96" |

| Thickness Options: | Isolation • Hydro • Custom |

| Rating Classes: | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Stocked Alloys: | 516-Gr70 CS • 304/316 SS (Any Available Alloy) |

| Materials Origin: | USA |

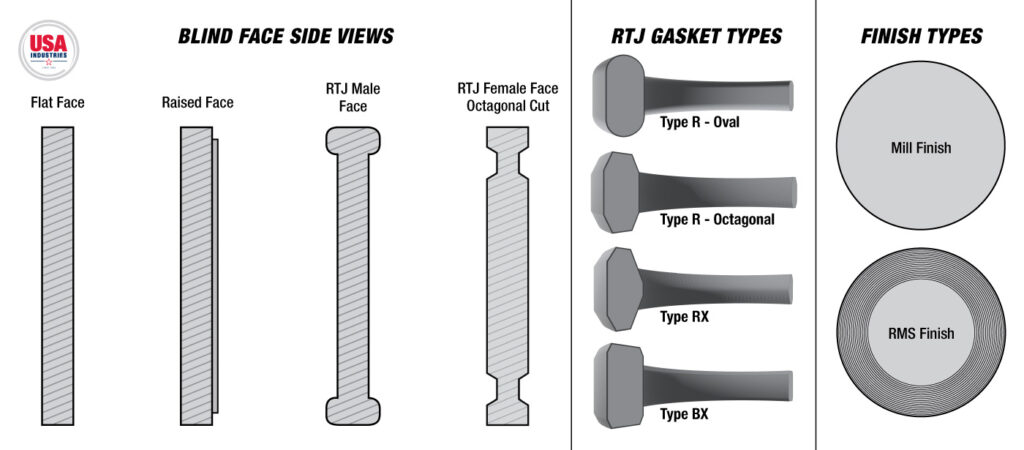

| Face Options: | Flat • Raised • RTJ Male • RTJ Female |

| Gasket Types: | Octagonal • Oval |

| Finish Options: | Serrated (125/250 RMS) • Mill |

| Coating Options: | Various |

| ASME Standards: | B16.48 • B16.47 (26" & Larger - Series A & B) • B16.5 |

| NSF ANSI/CAN 61 Certification: | NSF ANSI/CAN 61 certification applies exclusively to our stainless steel products |

To Order Call:

(800) 456-8721

Specify:

- Flange Rating (150#, 300#, 600#, 900#, 1500#, 2500#)

- Size (1/2" - 96")

- Face Type (Flat, Raised, RTJ - Male or Female (if Female: Oval or Octagonal cut)

- Mill or Serrated Finish

- Blind Thickness (Isolation, Hydro, Custom)

- Steel Material Type (Carbon, Stainless - 304, 316, Other)

- Quantity Needed

- Necessary Delivery Date

Why USA Industries?

40+ years of manufacturing excellence and innovation

Fastest Turnaround

Same-day shipping on stock items. Custom orders in days, not weeks.

Manufactured In-House

U.S. produced steel, PMI verified, QC certified.

ISO 9001:2015 Certified

Quality-driven manufacturing process ensures excellence.

Color-Coded Handles

Easy rating identification with color-coded handle system.

100% USA Materials

All raw materials sourced from American mills.

Blind

Processing

What separates USA Industries blinds from the competition — built into every piece.

Why Our Blinds Are Different

We are the actual manufacturer, not just a reseller. Since 1982, using advanced CNC plasma and waterjet machines, each blind is crafted with engineered symmetry, clean edges, fresh paint (carbon steel), marked or stamped, and color-coded handles for easy flange rating identification. Also, our blind solutions are crafted from top-grade, American milled alloys, including carbon steel, stainless steel, and other specialized materials known for their strength, durability, and corrosion resistance.

Moreover, unlike others who may claim this, USA Industries has the largest stock for immediate delivery and in-house production.

Additional Information

Need Blind Storage?

Protect Your 1/2"–14" Paddle Blinds with the Patented EZ Lock Blind Rack®

Rent or Buy the Patented EZ Lock Blind Rack from the Industry Leader in Blind Storage Solutions!

- Safely store and organize paddle and spectacle blinds

- Stackable design for 16" and larger blinds

- Rental and purchase options available

- Reduces handling damage and improves organization

USES FOR SPECTACLE BLINDS:

- Primary Use – Flow Shutoff: When the solid disc is aligned with the pipeline, it blocks fluid or gas flow, allowing maintenance on downstream equipment without shutting down the entire system.

- Pressure Testing: Creates a temporary seal during hydrostatic or pneumatic tests to verify structural integrity and detect leaks or defects.

- Flow Regulation: By rotating the the handle position so that the open disc aligns with the pipeline, it allows operators to partially or fully obstruct flow or divert it to alternative routes for better process control.

Spectacle Blind 3D Product Rotation

Spectacle blinds, also known as spectacle flanges and figure-8 blinds, have two metal discs connected by a handle, resembling a pair of spectacles. While one disc is solid, the other features a hole or opening, enabling flow through the system when aligned with the pipe or vessel. We manufacture our figure-8 blinds from single machined metal pieces, eliminating the need for separate paddle blinds and spacers during pipe maintenance isolation.

USA Industries NSF ANSI/CAN 61 certification applies exclusively to our stainless steel products.

NSF/ANSI 61 is the NSF standard ensures that any materials, coatings, or products that come into contact with drinking water do not leach harmful contaminants into the water at unsafe levels.

NSF 61 Covers:

- Pipes & fittings (metal, plastic, concrete, etc.)

- Valves & gaskets

- Meters & water treatment devices

- Coatings, linings, sealants, solders

- Any materials that touch drinking water in distribution systems

It Tests For:

- Leaching of lead, arsenic, mercury, and other heavy metals

- Leaching of organic contaminants (e.g., solvents, plasticizers)

- Other harmful chemicals that might migrate from the material into water

Why It Matters:

- It’s a regulatory requirement in most U.S. states and Canadian provinces for products used in public water systems.

- Products with NSF/ANSI 61 certification give assurance that they are safe for use with potable (drinking) water.

Technical Documentation

Frequently Asked Spectacle Blind Questions

Yes. We refer to this as a blind spacer set. We typically manufacture this configuration on larger sizes.

Yes. We will make these in any alloy that you require, and is available.

Let us know what ID you need and we will manufacture them to the specification you provide to us.

Tell us the thickness you need and we will manufacutre it to that specification.

On small spec blinds the web typically fits between the bolt holes. On larger spec blinds it's common to drill a hole in the center of the web for a bolt to fit through which holds the blind in place. If you want the tie-bar to be made differently, let us know.

Mill finishes or machined 125-250 RMS finishes are the most common finishes we produce, but we can finish them however you like. Additionally, RTJ (RJ) gasket surfaces can be provided in oval or octagonal form.

Yes. Let us know how you want the additional thickness machined down from the outside diameter to the raised face gasket area. This is not common and will require an additional fee.

Yes. First, we need to know if you prefer an RTJ (RJ) male or RTJ (RJ) female spectacle blind.

For a male RTJ blind, the gasket profile is machined onto the blind, but this isn't usually preferred because any damage to the gasket profile will render it unusable. For a female RTJ blind, the area for the gasket seating profile is machined into the blind. This is preferred because commonly available gaskets can be used between the blind and flange.

We also need to know the profile you'd like on your gasket surface.

For male RTJ blinds, the options are oval or octagonal. Female RTJ blinds are typically requested as octagonal, which has 3 sides on each mating area (like a flat bottom V).

We can accommodate whatever combination you require for your blinds!

Yes. We will manufacture your blind(s) with any additional feature you need.

Yes, carbon or carbon alloy steel spectacle blinds will be color coded in the webbing of the blind.

150#: Red

300#: Blue

600#: Yellow

900#: Green

1500#: White

2500#: Orange